Key Specifications / Features

The Flanged Knife Gate Valve Plant in China offers robust valves designed for heavy slurry applications. These valves feature a ductile iron or carbon steel body, ensuring durability and strength. The SS 316L gate and rubber sleeve provide excellent corrosion resistance and sealing performance. Available in sizes ranging from DN80 to DN1500 (3-60 inches) and pressure ratings of PN2 to PN6, these valves are ideal for handling heavy slurry in various industrial processes.

- Model No.: MV-20250604-KGV-01

- Hits: 5

- Categories: Cast Steel Gate Valve

- Tags: Flanged Gate Valve, Rubber Sleeved Gate Valve, Knife Gate Valve

Detail Information

Product Name: Flanged Knife Gate Valve

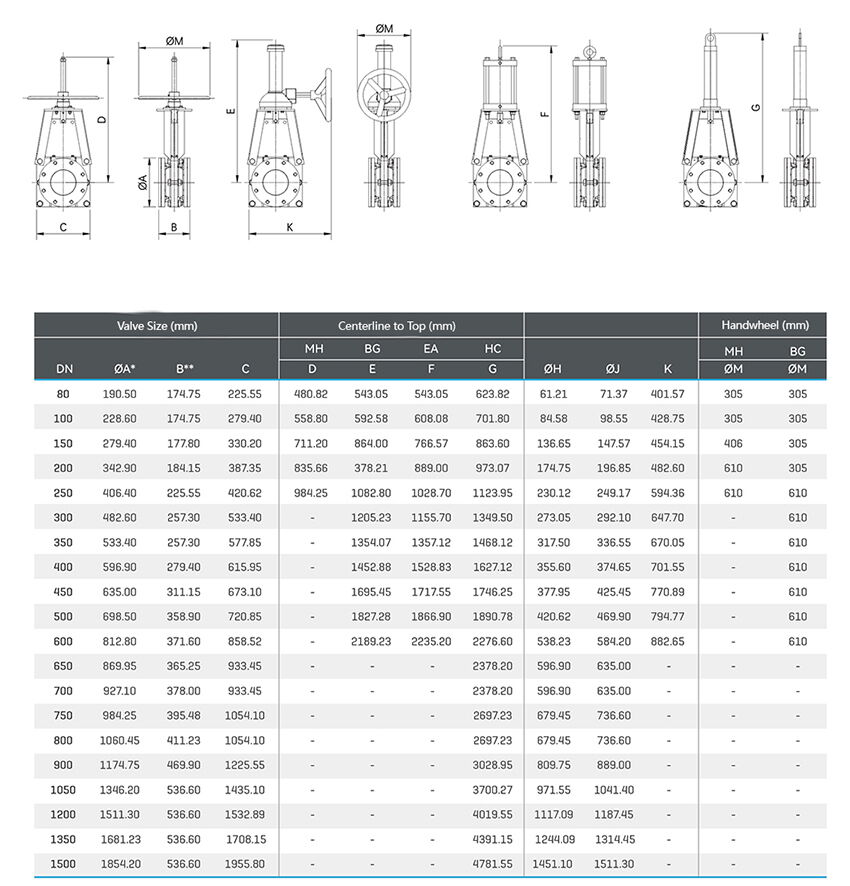

Size Range: DN80–DN1500, 3-60 Inch

Pressure Rating:

DN80–DN600: 6 bar, PN6

DN650–DN1050: 5 bar, PN5

DN1200–DN1350: 3 bar, PN3

DN1500: 2 bar, PN2

Operating Temperature: Standard sleeve up to 75°C, maximum 180°C

Sleeve Material: Pure Rubber Compound

The flanged knife gate valve is equipped with heavy-duty, full-port elastomer sleeve, providing ultimate shutoff for heavy slurry applications.

Standard Configuration

Ductile iron or carbon steel body

SS 316L stainless steel gate plate

Carbon steel actuator mounting bracket

Flat body flanges compatible with international flange dimensions

Natural rubber sleeves and sealing gaskets for standard temperature

DN250–DN1500 with carbon steel retainer flanges and natural rubber seals

Lining Configuration

Internal reinforcement ring

Maintains roundness

Resists shear forces during operation

Protects internal sealing surfaces

Product Features

Designed to meet various requirements for abrasion, corrosion, temperature, and pressure;

Functions both as a pump body and for slurry handling, performing effectively even with ungranulated and high-density materials;

Provides 100% isolation with bubble-tight sealing for absolute zero leakage;

Heavy-duty, field-replaceable elastomer sleeves with internal reinforcement rings;

Double-gate design enables bi-directional flow sealing;

Unobstructed or dynamically stabilized airflow minimizes valve pressure drop;

Prevents any solid particle accumulation on the gate that could hinder valve closure;

No metal parts are exposed to slurry contact;

No need to adjust or lubricate packing, eliminating leakage and maintenance issues;

Flexible frame (bracket) design allows for installation onto existing gate stem nuts.

Applications: Mining, Mineral Processing, Power Generation, Chemical Industry, Pulp and Paper Industry, Cement Industry