(API 624 Additional High Temperature Version)

Key Specifications / Features

Our China-based factory manufactures MSS SP-81 knife gate valves with a robust GGG40 ductile-iron body and a corrosion-resistant SS 304 stainless-steel gate. Available in sizes 2–16 in. (DN50–DN400) and rated Class 150 LB, the valves feature wafer-style ends for easy installation between flanges and are operated by a durable handwhee

- Model No.: MV-20250709-CSGTV-01

- Hits: 18

- Categories: Cast Steel Gate Valve

- Tags: MSS SP-81 Gate Valve, Knife Gate Valve, GGG40 Gate Valve

Detail Information

Product Name: GGG40 Knife Gate Valve

Design Standard: MSS SP-81, JB/T 8691-2013

Body Material: GGG40

Gate Material: SS 304

Size Range: DN50-DN400, 2-16 Inches

Pressure: PN10, PN16, Class 150 LB

Connection Method: Wafer

Test Standard: API 598, GB/T 13927-2008

Packing: Aramid, High Water Base, PTFE (Teflon), Rubber

Stem Type: Rising/Non-rising Stem

Operation: Handwheel

Product Description

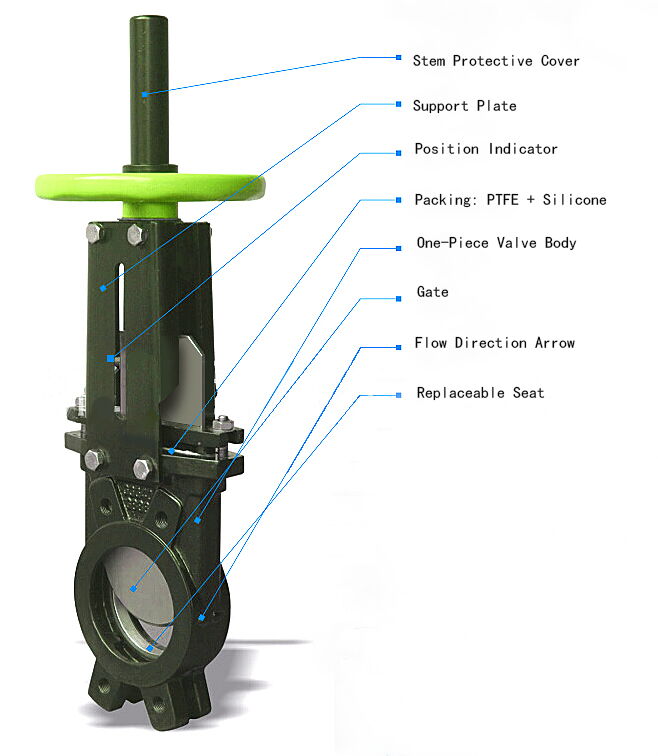

The non-slotted knife gate valve, also known as a bi-directional sealing knife gate valve, features a one-piece cast iron body. The valve consists of a body, a gate, and U-shaped sealing strips. The left and right sides of the valve body, as well as the bottom of the central cavity, are equipped with grooves that hold elastic U-shaped sealing strips. When the valve is closed, the gate moves downward, and the bottom edge of the gate comes into contact with the sealing strip, compressing it into the groove to achieve a seal between the valve body and the gate. When the knife gate valve is opened, the gate moves upward, and the bottom edge of the gate disengages from the sealing strip, allowing it to spring back and become flush with the groove. This design prevents the accumulation of sediment in the valve cavity during use, avoids clogging and residue, and facilitates pipeline cleaning. As a result, the sealing performance of the knife gate valve is effectively improved, and leakage when the valve is closed is prevented.

Product Features

The bottom of the gate is designed with a beveled edge.

The valve body is equipped with wedges on both sides.

These two features ensure proper positioning when the gate is closed, effectively extending the service life of the sealing ring.

The two-piece innovative bracket design enhances the strength of the bracket.

The valve body includes a flow-guiding design to prevent fluid from stagnating in the valve cavity.

PTFE limit blocks prevent the gate from contacting the valve body, thereby extending the service life of the gate.