(API 624 Additional High Temperature Version)

Key Specifications / Features

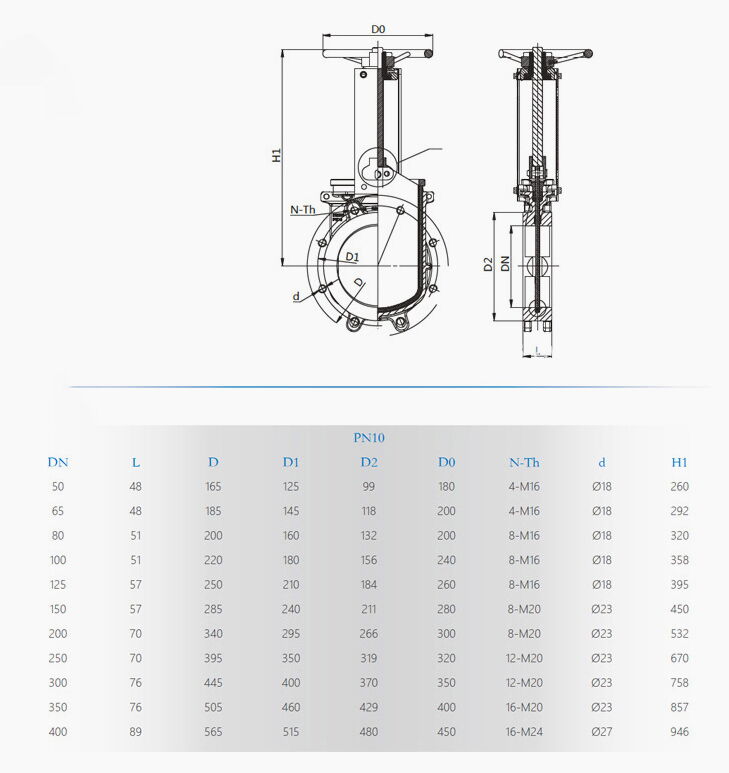

The MSS SP-81 Knife Gate Valve is a high-quality stainless steel valve designed for reliable performance in various industrial applications. It features a stainless steel body, ensuring durability and resistance to corrosion. The valve is available in sizes ranging from DN50 to DN400 (2-16 inches) and offers bidirectional sealing capabilities for enhanced reliability. With pressure ratings of PN10 and PN16, it can handle a variety of flow conditions. The wafer ends design allows for easy installation and integration into existing systems. Equipped with quality packing, this valve ensures minimal maintenance and long-term service life.

- Model No.: MV-20250705-CSGTV-01

- Hits: 11

- Categories: Cast Steel Gate Valve

- Tags: Stainless Steel Gate Valve, MSS SP-81 Gate Valve, Knife Gate Valve

Detail Information

Product Name: Knife Gate Valve, Bidirectional Sealing

Design Standard: MSS SP-81, JB/T 8691-2013

Body Material: Stainless Steel

Size Range: DN50-DN400, 2-16 Inches

Pressure: PN10, PN16, Class 150 LB

Connection Method: Clamp (Wafer)

Test Standard: API 598, GB/T 13927-2008

Packing: Aramid, high Water Base, PTFE (Teflon), Rubber

Stem Type: Rising/Non-rising Stem (Handwheel)

Part Material Table

|

No. |

Part Name |

Ductile Iron (GGG/SS) |

Stainless Steel CF8M (ASTM) |

|

1 |

Body |

GGG40 |

ASTM A351 CF8M |

|

2 |

Disc |

SS 304 |

SS 316 |

|

3 |

Support Ring |

SS 304 |

SS 316 |

|

4 |

Sealing Surface |

EPDM or metal |

SS 316 or Viton |

|

5 |

Packing |

PTFE+Silicone |

PTFE+Silicone |

|

6 |

Bonnet |

GGG40 |

ASTM A351 CF8M |

|

7 |

Position Indicator |

SS 410 |

SS 316 |

|

8 |

Stem |

X20Cr13 |

ASTM A276 316 |

|

9 |

Nut |

ASTM B148 C95200 |

ASTM B148 C95200 |

|

10 |

Support Plate |

St33 |

SS 304 or St33 |

Double Seal Knife Gate Valve Description

The valve features an integrated structure with a cast iron body, gate, and U-shaped sealing strip.

The body has grooves on both sides and at the bottom of the chamber, fitted with elastic U-shaped sealing strips.

When the valve is closed, the gate moves down to compress the sealing strip into the grooves, ensuring a tight seal between the body and the gate.

When the valve is opened, the gate lifts, releasing the sealing strip which then springs back to a flat position with the grooves.

This design prevents medium sediment from accumulating in the grooves, avoiding blockages and residue, facilitating pipeline cleaning, and enhancing the valve's sealing performance to prevent leaks upon closure.

Product Features

The gate has a bottom bevel design.

The body includes wedge blocks on both sides.

These features ensure the gate's limiting position when closed, effectively extending the life of the seal.

The two-piece new-style support increases the strength of the support structure.

The body is designed with a flow guide to prevent fluid stagnation within the valve chamber.

A PTFE limit block ensures the gate does not contact the body, prolonging the gate's service life.