Key Specifications / Features

The Polyurethane Lined Knife Gate Valve Manufacturer specializes in producing wear-resistant slurry valves designed for demanding industrial applications. These valves are fully lined with polyurethane, offering exceptional durability and resistance to abrasion. Available in sizes ranging from DN50 to DN750 (2-30 inches) and pressure ratings of PN10 to PN25, they feature a full bore design to ensure maximum flow efficiency.

- Model No.: MV-20250604-KGV-04

- Hits: 6

- Categories: Cast Steel Gate Valve

- Tags: Knife Gate Valve, Polyurethane Lined Gate Valve, Full Bore Gate Valve

Detail Information

Product Name: Polyurethane (PU) Lined Knife Gate Valve

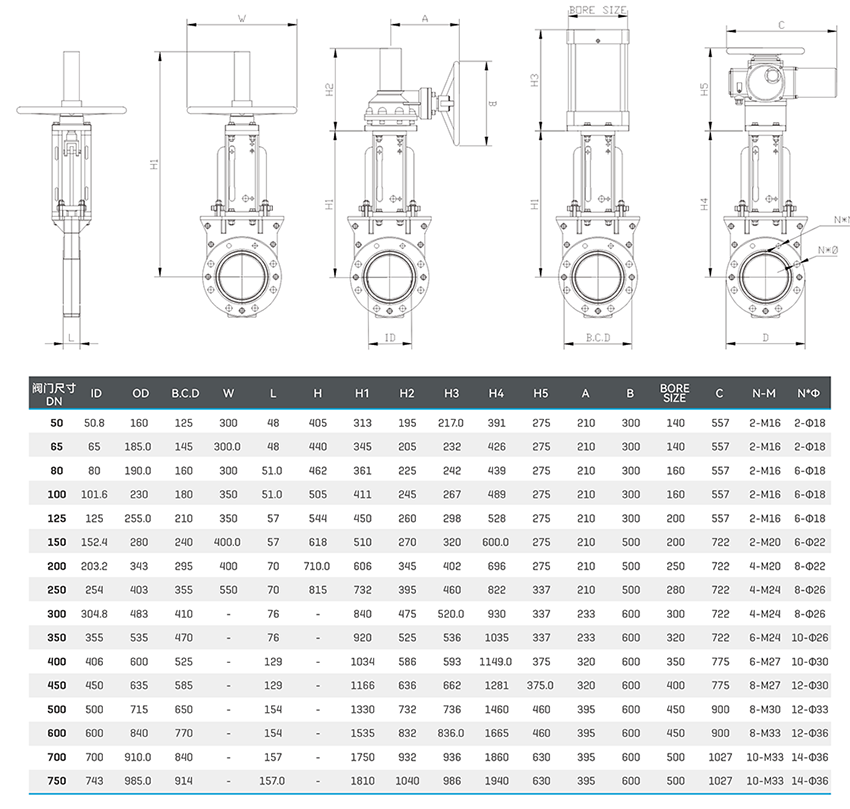

Size Range: DN50–DN750, 2-30 Inch

Temperature: -40°C to +80°C

Pressure Rating: PN10, PN16, PN25, Class 150-300 LB

Lining Material: Polyurethane (PU)

Application Areas: Mineral Processing, Power Plants, Pulp & Paper, Municipal Systems, Food Manufacturing

A wear-resistant slurry valve featuring an innovative fully-lined polyurethane structure, offering a significant leap in service life and sealing performance for mining and slurry applications.

Product Features

Vortex Cleaning Closure: The beveled bottom of the gate redirects media flow during closure, creating a flushing vortex that clears valve seat deposits, ensuring 100% zero leakage with every shutoff.

Full Bore Design: The flow path matches the pipe inner diameter, eliminating turbulence and minimizing erosion.

Full Open Position: Gate retracts completely into the valve cavity, avoiding direct media impact and extending gate service life.

Fully Lined Valve Body: The one-piece molded abrasion-resistant polyurethane liner encases all internal surfaces, delivering seamless wear protection with no dead zones.

Superior Polyurethane Performance: The polyurethane used contains urethane-type repeating units with exceptional abrasion resistance—8× harder than tungsten carbide steel, 7× that of vulcanized rubber, and 3× that of UHMWPE, especially under immersion.

Self-Flushing Seat Design: A unique gate and seat configuration prevents media buildup and jamming during closure.

Gate Scraper: Integrated blade cleans the gate during operation, preventing build-up and reducing actuation torque.

Replaceable Wear Parts: The gate and liner are designed for easy on-site replacement, improving efficiency and reducing downtime.