(API 624 Additional High Temperature Version)

Key Specifications / Features

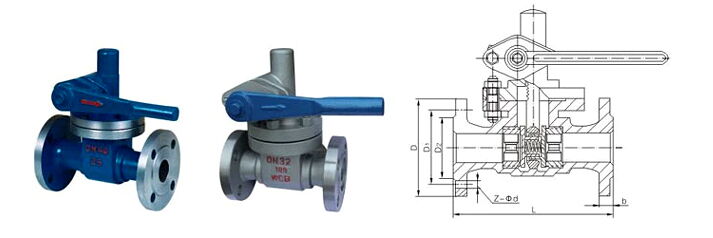

Discover top-quality quick blowdown valves from a leading plant in China. These valves feature a carbon steel ASTM A216 WCB body and graphite packing, ensuring durability and reliability. Available in sizes ranging from DN25 to DN100 (1 to 4 inches) and pressure ratings from PN16 to PN40 (Class 150 to 400 LB), they are designed to meet diverse industrial needs. Equipped with flanged ends for secure and easy installation, these valves offer efficient blowdown solutions in various applications.

- Model No.: MV-20250703-CSGTV-01

- Hits: 10

- Categories: Cast Steel Gate Valve

- Tags: Quick Blowdown Valve, Carbon Steel Blowdown Valve, ASTM A216 WCB Blowdown Valve

Detail Information

Product Name: Quick Blowdown Valve

Body Material: Carbon Steel ASTM A216 WCB

Packing: Graphite Yarn

Size Range: DN25-DN100, 1-4 Inch

Pressure Range: PN16, PN25, PN40, Class 150-400 LB

End Connection: Flanged

Working Temperature: up to 350°C

Medium: Water, Steam, etc.

Main Standards

Design and manufacturing: GB/T 12237-1989

Inspection and test: GB/T 13927-1992

Flange Dimensions: GB/T 17241.6-98

Pressure-temperature rating: GB 9131

Compression spring: GB/T1239.2

Structural length: JB/T6900-93

Marking: GB/T12220-1989

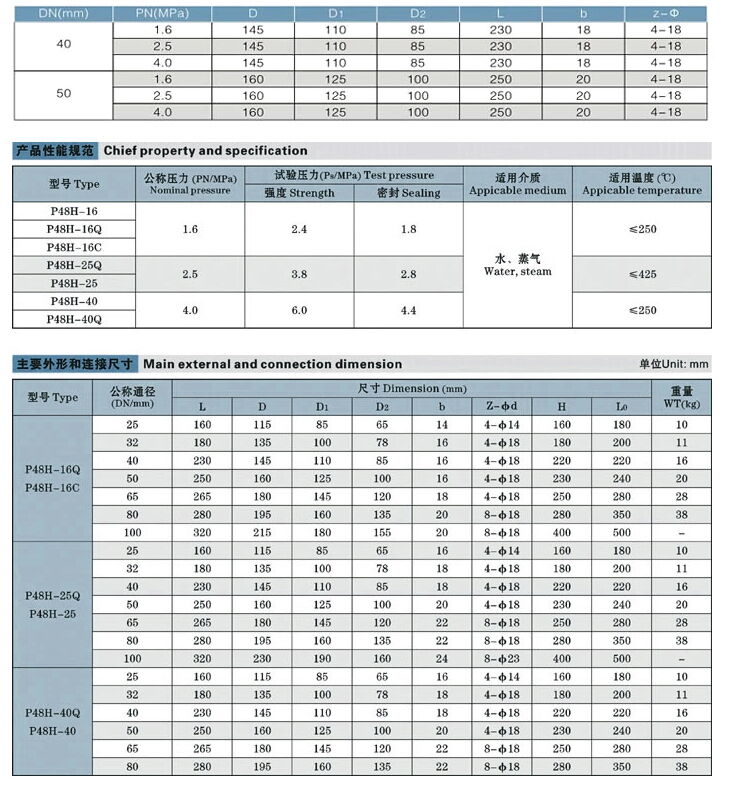

Performance Specifications

|

Model |

Z44H-16C |

Z44H-25 |

Z44H-40 |

|

Pressure |

1.6MPa |

2.5MPa |

4.0MPa |

|

Applicable Temperature |

≤350°C |

||

|

Applicable Medium |

Water, Steam |

||

Main Component Materials

|

Component Name |

Material |

|

Body, Bonnet |

Cast Steel ASTM A216 WCB |

|

Valve Stem, Gear Shaft |

Stainless Steel 2Cr13 |

|

Valve Disc, Seat |

Stainless Steel 2Cr13 |

|

Packing |

Graphite Yarn |

|

Handle |

Cast Steel ASTM A216 WCB |

|

Spring |

Phosphor Bronze Wire |

Overview of Quick Blowdown Valve

The quick blowdown valve is derived from the gate valve, utilizing a gear rotation of 90° to drive the valve stem to achieve the purpose of opening and closing. The quick blowdown valve is not only structurally simple and well-sealed, but also has a small volume, light weight, low material consumption, and small installation size, especially with a small driving force, simple operation, and easy to achieve fast opening and closing.

Quick Blowdown Valve Structural Principle

The quick blowdown valve directly relies on the pressure generated by the medium to assist in sealing the mechanical force on the valve flap. The mechanical load on the valve flap is mainly from the pressure spring, which is almost a fixed mechanical load. Although for the pressure spring, the loaded blowdown valve can adjust the spring to achieve good sealing, the sealing pressure must be strong enough to ensure sufficient sealing force, so that the valve can operate normally and seal properly. The sealing pressure difference should also be less than the opening pressure difference to ensure flexible operation.