(API 624 Additional High Temperature Version)

Key Specifications / Features

The ASTM A216 WCB Lift Check Valve is a robust industrial valve designed for reliable flow control. It features a cast carbon steel body, ensuring durability and strength. The valve is designed in accordance with BS 1868 standards, offering a DN100 (4-inch) size with a pressure rating of PN16 and a class of 150 LB. It has RF flanged ends for secure connections and includes a handwheel for easy operation.

- Model No.: MV-20250630-CSCV-01

- Hits: 16

- Categories: Cast Steel Check Valve

- Tags: ASTM A216 WCB Check Valve, Lift Check Valve, BS 1868 Check Valve

Detail Information

Product Name: ASTM A216 WCB Lift Check Valve

Design Standard: BS 1868

Body Material: ASTM A216 WCB

Size: DN100, 4 Inch

Pressure: PN16, Class 150 LB

End Connection: RF Flanged

Operation: Handwheel

Face to Face Standard: ASME B16.10

Test & Inspection Standard: API 598

Certificates: TA-Luft, ISO 15848-1, API 622, ect

Product Range

Body Material: ASTM A216 WCB, A217 WC6, A352 LCB

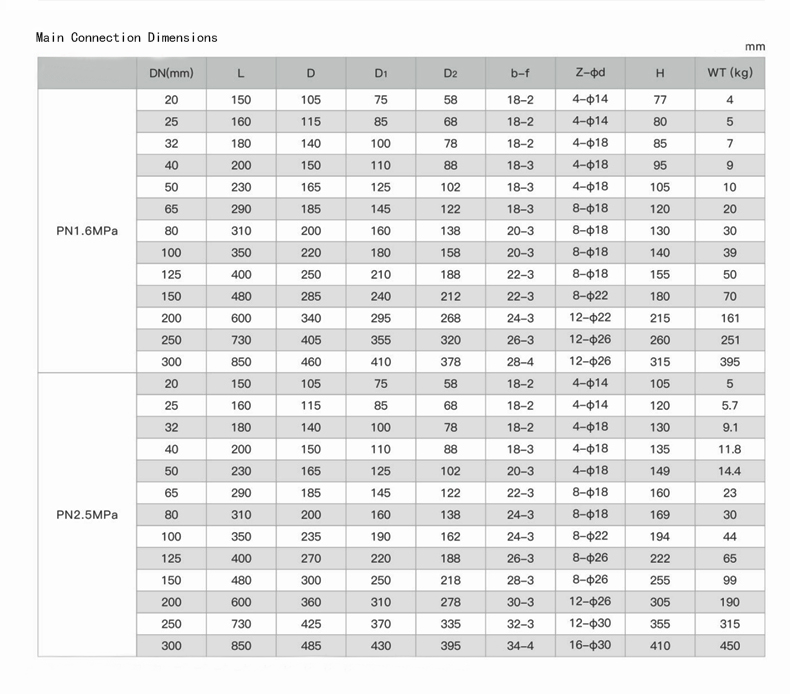

Size Range: DN20-DN300, 3/4-12 Inch

Pressure Range: PN16-PN160, Class 150-900 LB

Standards

Design Standard: BS 1868, GB/T 12235

Pressure Temperature Rating: ASME B16.34, GB/T 12224

Structural Length: ASME B16.10, GB/T 12221-2005, GB/T 15188.1

Flange Pattern Dimensions: ASME B16.5, GB/T 9113-2010, JB/T 79-2015

Inspection and Testing: API 598, GB/T 26480, GB/T 13927

Product Application

The national standard lifting check valve is suitable for pipelines with a nominal pressure of PN1.6-16.0 MPa, working temperature range of -46 to 550°C in the oil, chemical, pharmaceutical, fertilizer, power and other industries to prevent medium backflow.

Product Features

The product has a compact structure, reliable sealing, excellent performance, and beautiful appearance;

The valve flap and seat sealing surfaces are clad with Co-based hard alloy, which is wear-resistant, corrosion-resistant, and scratch-resistant, with a long service life;

The material of parts and flange sizes can be reasonably selected according to actual working conditions or user requirements to meet various engineering needs.

|

Nominal Pressure (MPa) |

PN1.6 |

PN2.5 |

PN4.0 |

PN6.4 |

PN10.0 |

PN16.0 |

|

|

Test Pressure (MPa) |

Shell Test |

2.4 |

3.75 |

6.0 |

9.6 |

15.0 |

24.0 |

|

High Pressure Seal |

1.76 |

2.75 |

4.4 |

7.04 |

11.0 |

17.6 |

|

|

Low Pressure Seal |

0.6 |

||||||

Main Component Materials

|

No. |

Component Name |

Carbon Steel |

Alloy Steel |

Low Temperature Steel |

|

1 |

Valve Body |

ASTM A216 WCB |

ASTM A217 WC6 |

ASTM A352 LCB |

|

2 |

Valve Disc |

ASTM A216 WCB |

ASTM A217 WC6 |

ASTM A352 LCB |

|

3 |

Gasket |

Flexible Graphite + SS 304 |

Flexible Graphite + SS 304 |

Flexible Graphite + SS 304 |

|

4 |

Valve Cover |

ASTM A216 WCB |

ASTM A217 WC6 |

ASTM A352 LCB |

|

5 |

Double-headed Bolt |

35CrMoA |

35CrMoA |

35CrMoA |

|

6 |

Nut |

45# |

35CrMoA |

35CrMoA |

|

7 |

Spring |

60Si2Mn |

0Cr18Ni9(304) |

0Cr18Ni9(304) |

Note: The dimensions in this table are based on GB/T 9113, GB/T 10928 standards, and the structural length follows GB/T 12221 standards.