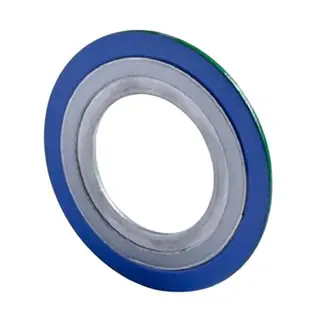

As a professional graphite gaskets manufacturer in china, we offer qulaity Graphite gaskets for your choices. These gaskets are widely used in various industrial applications due to their exceptional properties. They offer high resistance to corrosion, pressure, and temperature, making them ideal for demanding environments. These gaskets are made from soft yet incredibly strong materials, with a low friction composition that ensures effective sealing, reducing energy losses and heat build-up. The addition of filler materials further enhances their stability and tolerance. Graphite gaskets come in several types, including reinforced, tanged, foil, pure, unimetal, unigraph, and eyelet versions, each designed to meet specific requirements. The materials used range from pure graphite to graphite composites, with various metal core elements to improve performance in extreme conditions. These gaskets are known for their wide temperature range, flexibility, durability, and impermeability to gases and liquids. They are commonly used in high-pressure and temperature processes, such as those involving aggressive chemicals or steam, where stability and resistance are crucial.

Graphite Gasket Product List

Total 25 Records, 12 records per page