(API 624 Additional High Temperature Version)

Key Specifications / Features

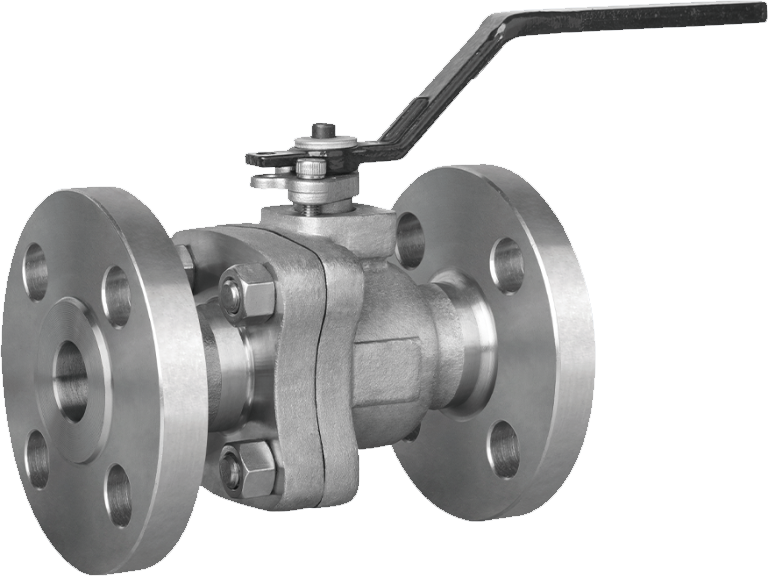

This three-piece ball valve is built for performance and easy maintenance. Made with a robust SS 304 stainless steel body and compliant with ASME B16.34 standards, it features a full port design for maximum flow. Sized at 1 inch (DN25) and rated at 1000 WOG / PN63, it’s suitable for high-pressure applications. The valve includes an anti-static device and low emission design, offering added safety and environmental protection—ideal for demanding industrial use.

- Model No.: MV-20250407-LTMSBV-02

- Hits: 14

- Categories: Low Torque Metal Seated Ball Valve

- Tags: 3 Piece Ball Valve, SS 304 Ball Valve, 1 Inch Ball Valve

Detail Information

Product Name: 3 Piece Ball Valve

Design Standard: ASME B16.34

Body Material: SS 304

Size: 1 Inch, DN25

Pressure: 1000 WOG, PN63

End: Flanged

Operation: Lever

Features

Full Port

Anti-static Device

Blow-out Proof Stem

ISO5211 Direct Mounting Pad

Locking Device Handle

Product Range

Body Material: ASTM A216 WCB, A351 CF8, CF8M

Nominal Diameter: DN15-DN150

Body Working Pressure: 1000 WOG (PN63)

Flange End Working Pressure: PN16/40, Class 150/300 LB

Working Temperature: -20°C to 180°C

Applications: Suitable for industries such as petroleum, chemical, natural gas, biochemical, pharmaceutical, environmental protection, and new energy

Standards

Design: ASME B16.34, GB/T 12237

Flange Dimensions: ASME B16.5, JB/T 79.1

Inspection & Testing: API 598, GB/T 13927, JB/T 9092

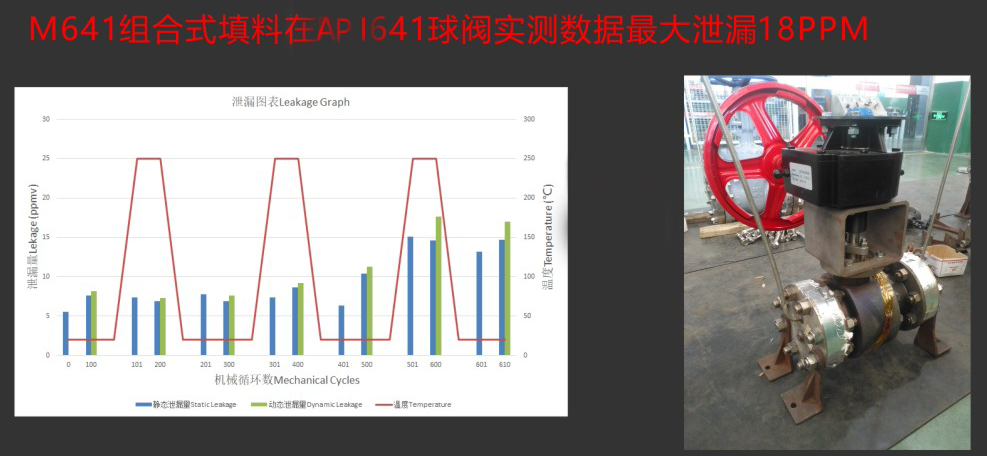

For ball valve packing rings, we exclusively use M641 specialty low-emission packing designed specifically for ball valves.

If conventional graphite packing rings are used in stock inventory, they can strongly adhere to the valve stem over time, leading to excessive operating torque and leakage issues during later use.

By adopting our low-emission packing, even after prolonged storage, the valve maintains:

-

Very low operating torque

-

Excellent sealing performance

-

No adhesion issues

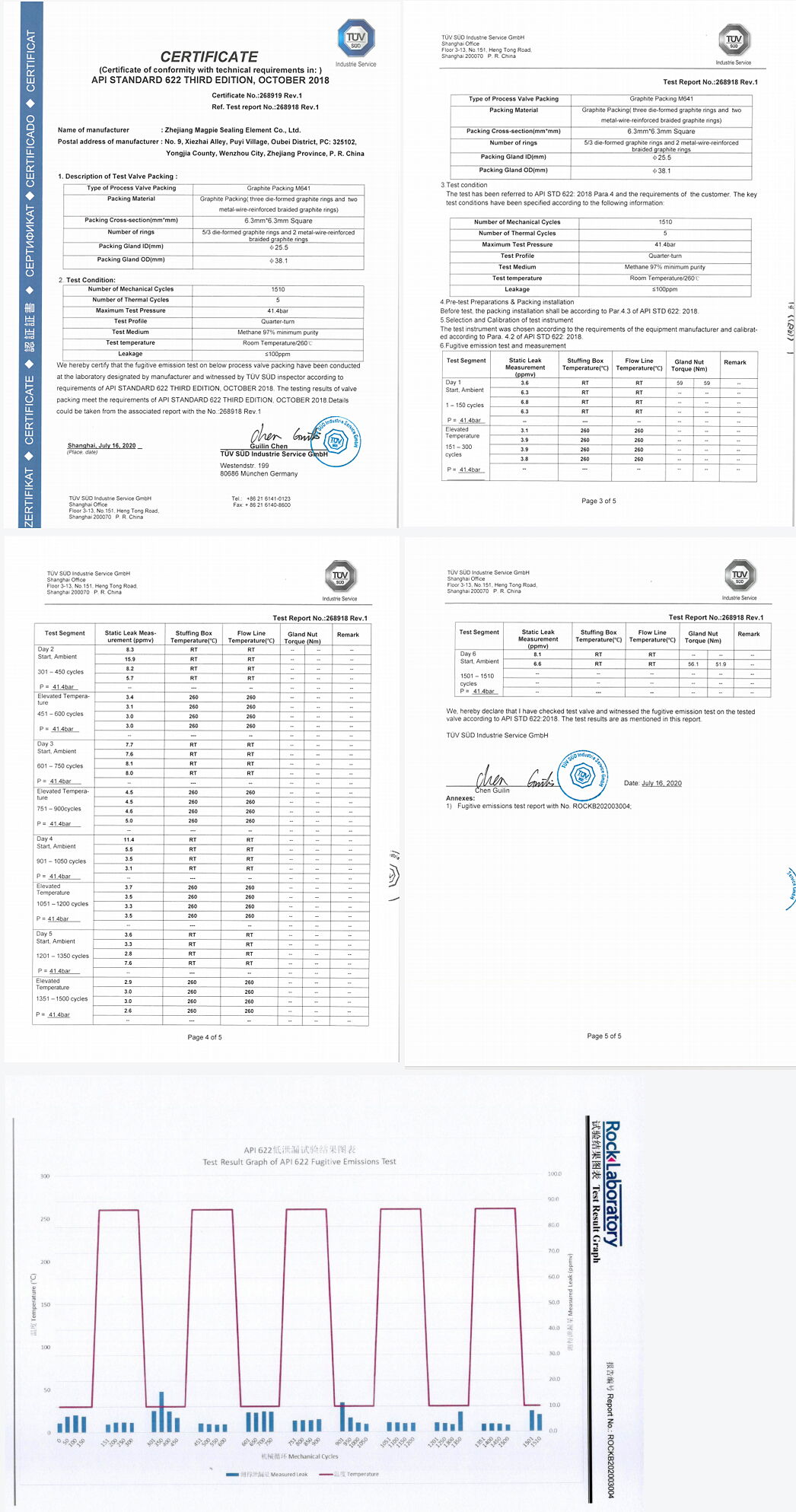

API 622 TUV Experimental Data Report

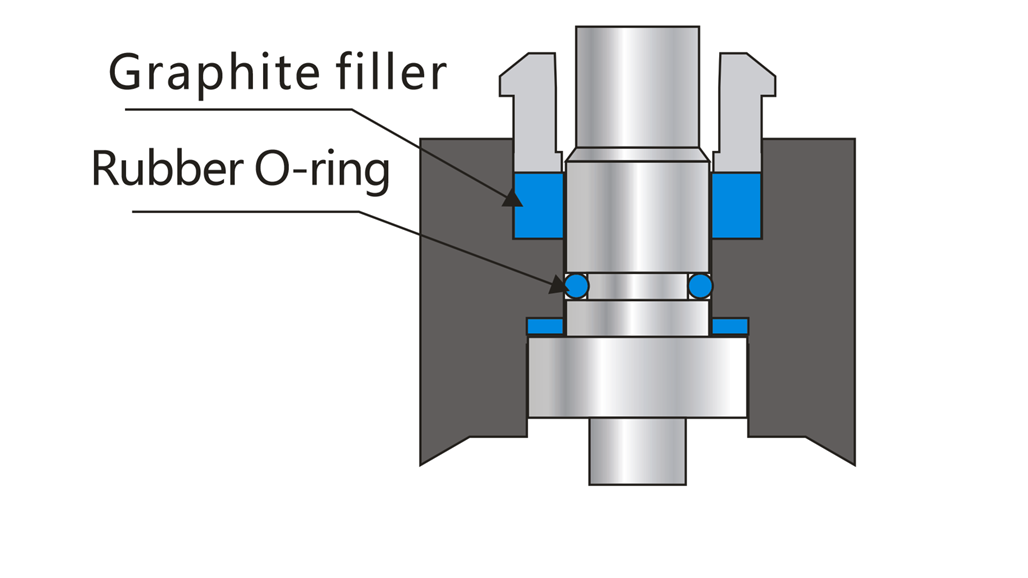

We have optimized the design of the packing structure for floating ball valves. Based on our field experience in petrochemical applications, we found that traditional designs using O-rings plus packing material may appear more reliable but actually create potential risks.

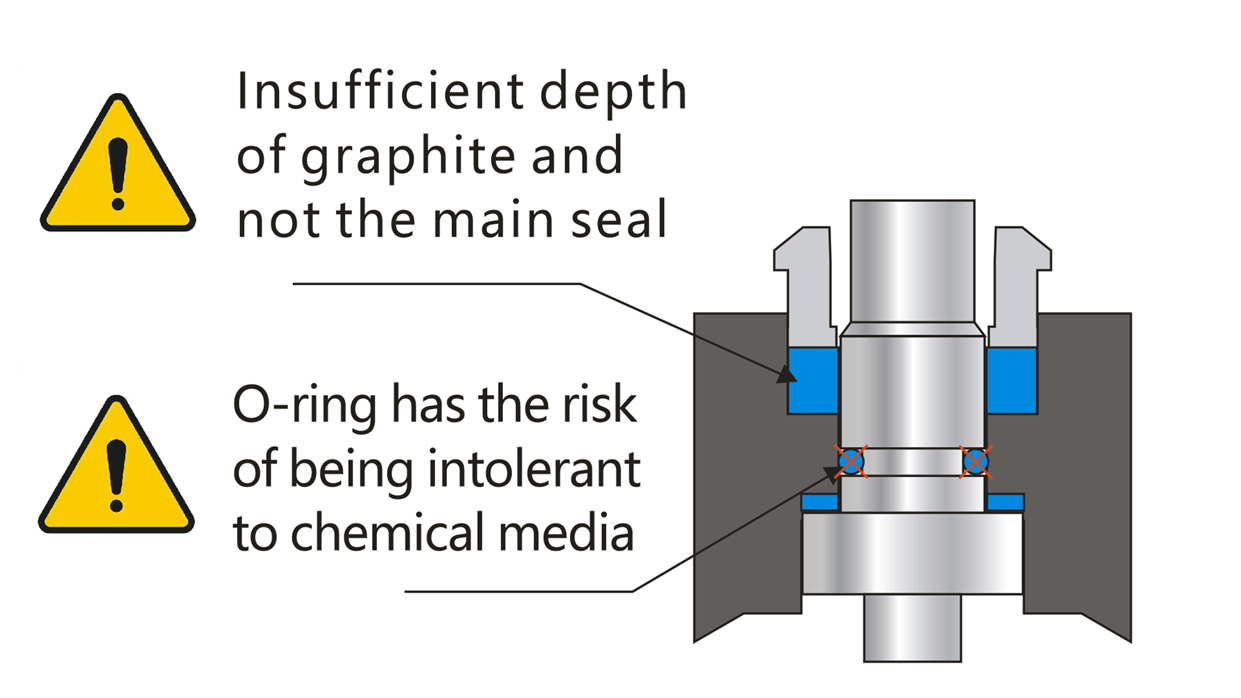

In conventional designs, the O-ring might become the primary seal while misleading users to believe the graphite packing also functions as a main seal. However, O-rings are vulnerable to chemical corrosion. Once the O-ring fails and the graphite packing is insufficient, both sealing mechanisms may fail, making it impossible to perform secondary pre-tightening on-site.

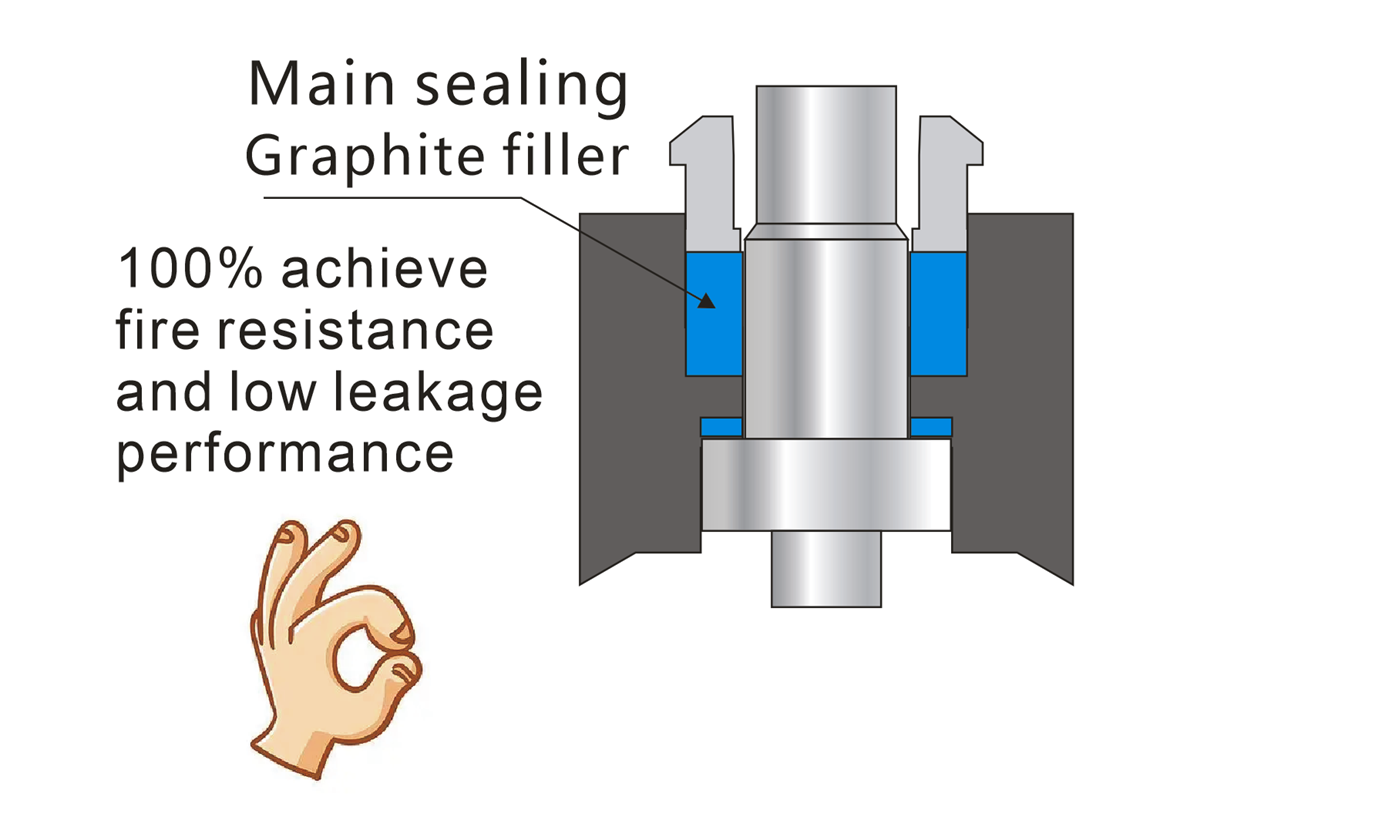

Additionally, our tests confirmed that insufficient graphite packing consistently fails fire safety tests. Therefore, we optimized the design by removing the O-ring and relying solely on packing as the primary seal. The benefits include 100% fire safety performance, 100% low leakage, and enhanced stem strength.

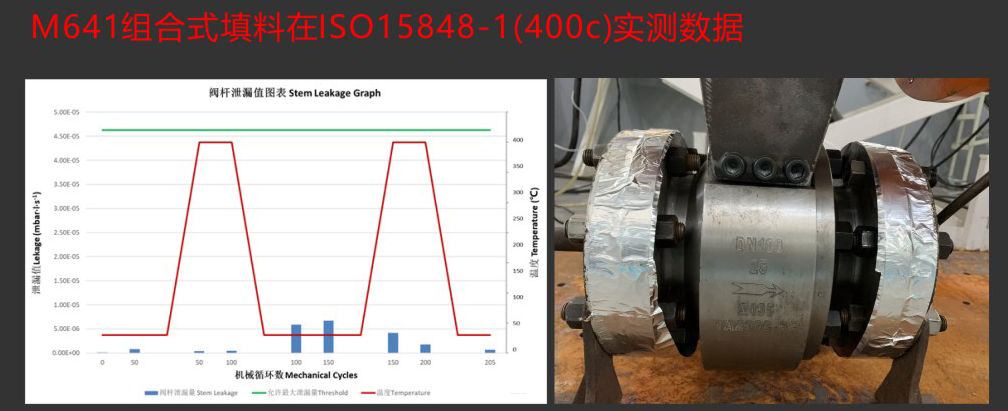

ISO 15848-1 Type Test Report at 400°C

Similar Products

3-piece Threaded Ball Valve, ASME B16.34, SS 304, 1/2 Inch

2-Piece Threaded Ball Valve, SS 304, 2 Inch, 1000 WOG, Lever

One Piece Ball Valve, ASME B16.34, A351 CF8M, 1 IN, 1000 WOG