(API 624 Additional High Temperature Version)

Key Specifications / Features

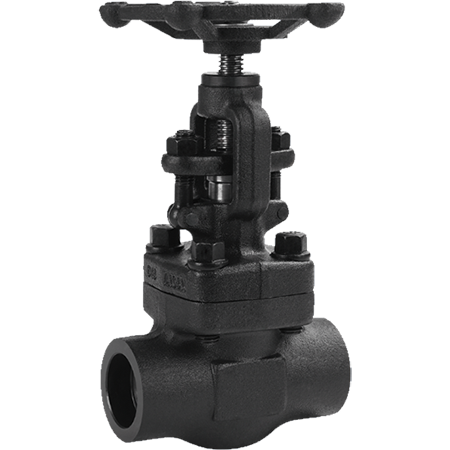

This ASTM A105N globe valve, manufactured by a reliable factory, features a forged carbon steel body and bellows sealing for enhanced performance and low emission. Compliant with DIN 3356 standards, it is designed with welded ends for secure installation. Sized at 1 inch (DN25) and rated for PN25 / Class 300 LB, this valve is ideal for high-pressure applications where leak-tight sealing and durability are essential.

- Model No.: MV-20250407-FSGLV-01

- Hits: 15

- Categories: Forged Steel Globe Valve

- Tags: Bellows Sealed Globe Valve, DIN 3356 Globe Valve, ASTM A105N Globe Valve

Detail Information

Product Name: Bellows Sealed Globe Valve, Bolted Bonnet

Design Standard: DIN 3356

Body Material: ASTM A105N

Size: DN25, 1 Inch

Pressure: PN25, Class 300 LB

End: Welded

Operation: Handwheel

Product Range

Size Range: NPS 1/2-6 Inch, DN15-DN150

Pressure Class: Class 150-1500 LB

Body Material: ASTM A105, A350 LF2, A182 F304/304L, F316/316L, etc.

Bonnet Type: Bolted Bonnet (BB), Welded Bonnet (WB)

Construction: Outside Screw and Yoke (OS&Y), Renewable Seat

Applicable Standards

Design: DIN 3356, ASME B16.34, API 602

Inspection and Testing: API 598

Marking: MSS SP-25

Pressure/Temperature Rating: ASME B16.34

Fugitive Emission Test: API 624

End Connections & Standards

Face to Face: ASME B16.10

End to End: Manufacturer Standard or ASME B16.10

Socket Welding Ends: ASME B16.11

Screwed Ends: ASME B1.20.1

Flanged Ends: ASME B16.5

Butt Welding Ends: ASME B16.25

The packing used in forged valves is the M800 series graphite packing,

with a graphite carbon content exceeding 99% and a sulfur content below 50 PPM.

The dynamic leakage rate, as tested according to API 622, is less than 12 PPM.

The static leakage rate is below 6 PPM.

All the gaskets used are low-emission gaskets certified by TÜV Rheinland TA-LUFT.

Type Test Report for 2-Inch Gate Valve

According to ISO 15848-1 at 400°C

Type Test Report for 1-Inch Globe Valve

According to ISO 15848-1 at 400°C

Type Test Report for 3/4-Inch Gate Valve

According to ISO 15848-1 at 400°C