Key Specifications / Features

This Class 1500 LB gate valve packing set is manufactured at a specialized factory and designed for high-performance sealing in critical applications. Compliant with API 622 standards, the low-emission packing set features graphite material reinforced with 20% Inconel wire for enhanced durability and thermal resistance. Measuring ID 68 mm x OD 88 mm and consisting of 6 rings, it is specifically engineered for use in API 6D gate valves, ensuring reliable, leak-free operation under high-pressure and high-temperature conditions.

- Model No.: MV-20250710-GP-01

- Hits: 23

- Categories: Graphite Packing

- Tags: Class 1500 LB Valve Packing, Graphite Valve Packing, Gate Valve Packing

Detail Information

Product Name: Low-Emission Packing Set for Class 1500 LB API 6D Gate Valve

Model: M600

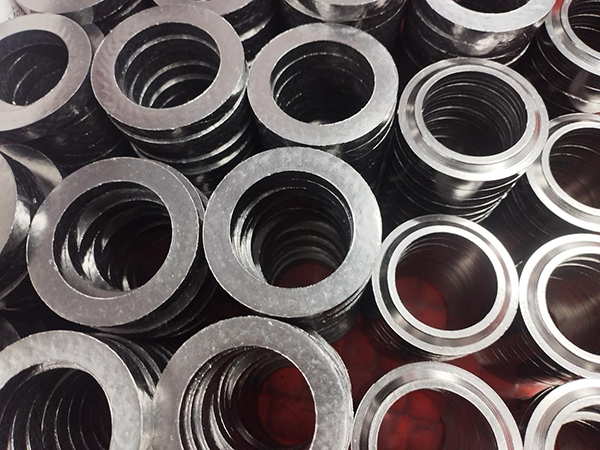

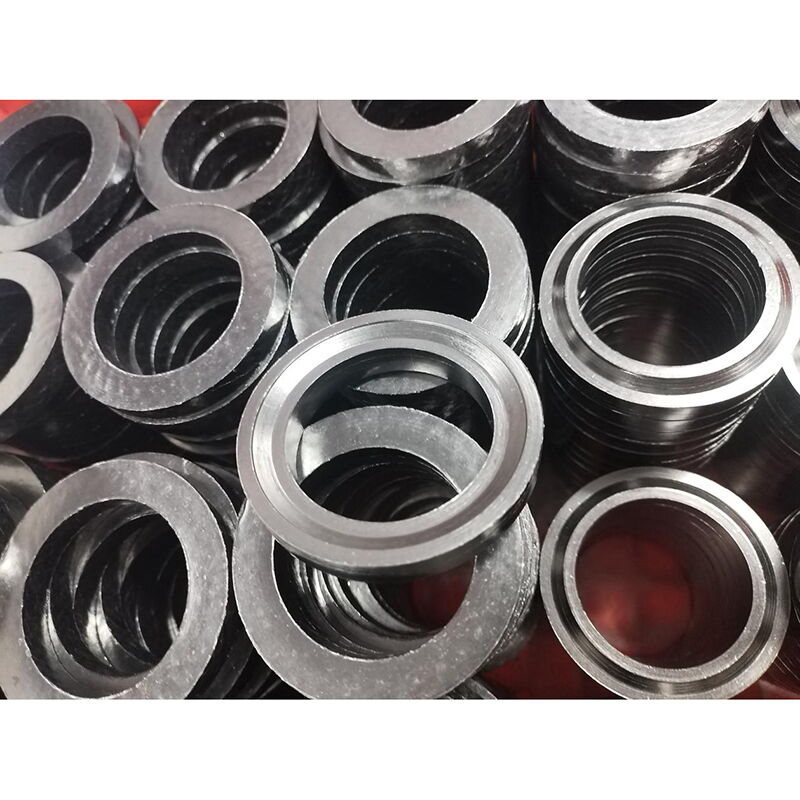

Size: ID 68 mm * OD 88 mm * 6 Rings

Material Properties:

Graphite Purity: ≥99%

Metal Wire Content: 20% (Inconel 600)

Sulfur Content: ≤50 PPM

Chlorine Content: ≤20 PPM

Operating Conditions: –45 °C to +425 °C

Certifications:

ISO 15848-1 (up to 400 °C)

TA-Luft

API 622 (incl. 400 °C fire-safe)

Operating Parameters

Speed: 2 m/s

Temperature Range: -200°C to +400°C (for most media), -200°C to +550°C (for steam)

pH Value: 0 to 14

Pressure: 25 MPa

Media: Suitable for most chemical substances (solvents, hydrocarbons, acids, alkalis, steam, alcohol, oil)

Except for strong oxidizing acids, such as sulfuric acid and nitric acid.

Design Rationale

Many gate/globe valve manufacturers still use conventional lathes rather than full CNC machining, resulting in wider machining tolerances.

Our solution employs a “butterfly” (convex-concave) graphite ring design that:

1. Generates higher deformation force to fill larger machining gaps.

2. Requires lower gland bolt preload, ensuring reliable high-pressure sealing.

Upper-and-lower braided end rings (density 2.5–2.6 g/cm³) transmit bolt load quickly to the centre pure-graphite rings, causing immediate deformation and sealing.

Once the centre rings reach ≥1.6 g/cm³ density, the end rings then deform to complete the seal—providing a stable, self-reinforcing sealing sequence.

Key Advantages

Compensating for larger machining tolerances common in gate/globe valve production.

Low gland bolt torque requirement reduces stem binding risk.

High-density braided end rings deliver rapid load transfer and excellent anti-extrusion performance.

Full compliance with international low-emission standards.