(API 624 Additional High Temperature Version)

Key Specifications / Features

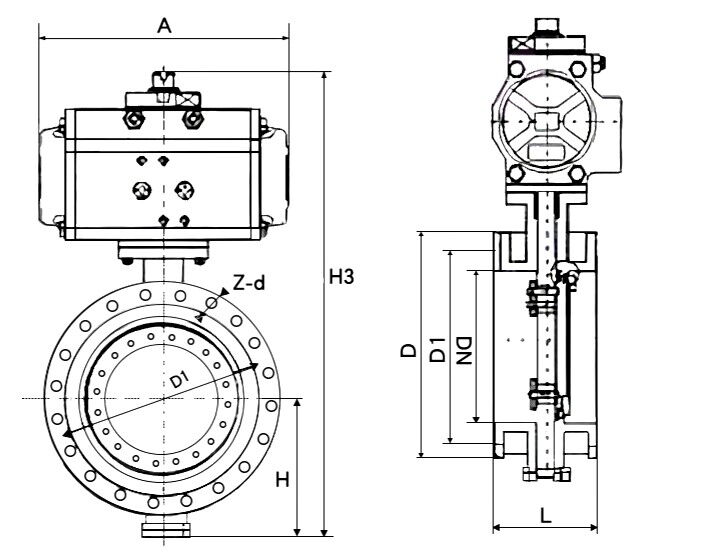

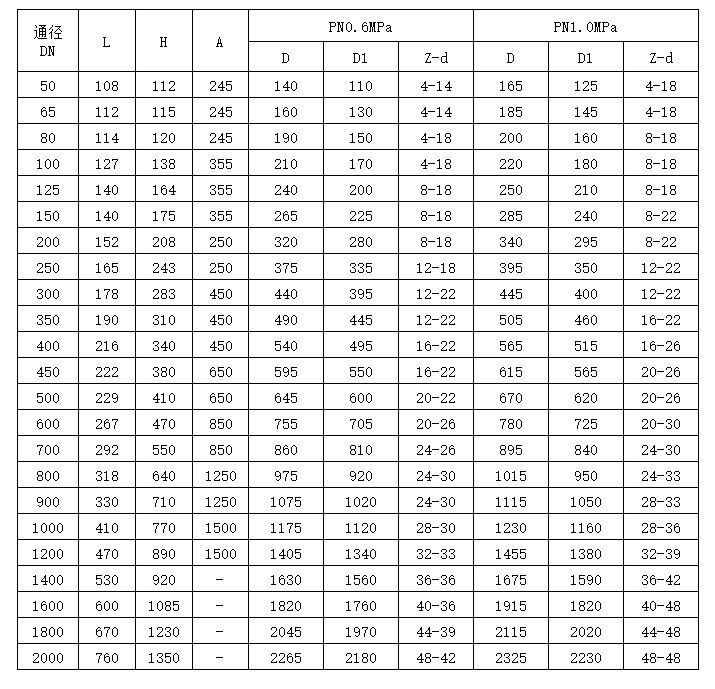

The Pneumatic Actuated Butterfly Valve offered by this manufacturer is designed for versatile industrial applications. It is constructed from high-quality materials such as cast steel (ASTM A216 WCB, QT450), and stainless steel (SS 304, SS 316), ensuring durability and corrosion resistance. Available in sizes ranging from DN50 to DN2000 (2-80 inches) and pressure ratings of PN6 and PN10, these valves feature flanged ends for easy installation and maintenance.

- Model No.: MV-20250716-BFV-04

- Hits: 10

- Categories: Cryogenic Butterfly Valve

- Tags: Pneumatic Actuated Butterfly Valve, Cast Steel Butterfly Valve, QT450 Butterfly Valve

Detail Information

Product Name: Pneumatic Actuated Butterfly Valve

Size Range: DN50-DN2000, 2-80 Inches

Pressure: PN6, PN10, Class 125 LB, 150 LB

Drive Method: Pneumatic Actuator

End Connection: Flanged

Applicable Medium: Water, Gas, etc.

Materials

Body Material: Cast Steel, ASTM A216 WCB, QT450, SS 304, SS 316

Disc Material: QT450, SS 304, SS 316, SS 316L

Shaft Material: 2Cr13

Sealing Ring Material: Viton

Packing Material: Flexible Graphite

The pneumatic flanged hard-sealed butterfly valve uses a precise U-shaped elastic sealing ring and a three-off-center multi-layer metal hard sealing structure. It is widely used in industries such as metallurgy, power, petrochemical, and municipal construction for media with temperatures ≤425°C, for regulating flow and cutting off the flow. This valve uses a three-off-center structure, with both the valve seat and disc sealing surfaces made of different hardness stainless steel, offering good corrosion resistance and a long service life. This valve has bidirectional sealing capabilities and meets the national GB/T 13927-92 valve pressure test standards.

Main Standards

|

Standard |

|

|

Manufacturing Standard |

GB/T 12237-89 |

|

Flange Standard |

GB 9113-2000, GB 17241.6-1998 |

|

Structural Length Standard |

GB 12221-89 |

|

Inspection Standard |

GB/T 13927-92 |

Product Features

- This valve uses a soft sealing structure, with tighter sealing as it closes, providing reliable sealing performance.

- The sealing auxiliary material uses Viton oil-resistant rubber, extending the service life.

- The rubber sealing ring can be located on the valve body or the disc, suitable for different media characteristics, offering users options.

- The disc uses a frame structure, high strength, large flow area, and low resistance.

- The whole body is coated, effectively preventing rust, and can be used with different media by simply replacing the valve seat sealing material.

- This valve has bidirectional sealing capabilities, not affected by the direction of the medium flow during installation, and can be installed in any direction.

- The unique structure of this valve makes it flexible to operate, labor-saving, and convenient.

Similar Products

Single-Acting Pneumatic Butterfly Valve, SS 304/SS 316, PN10

Powder Butterfly Valve, Aluminum Alloy, DN100-DN400, PN2-PN7

Sanitary Butterfly Valves, SS 304/316L, DN150-DN300, Clamped