(API 624 Additional High Temperature Version)

Key Specifications / Features

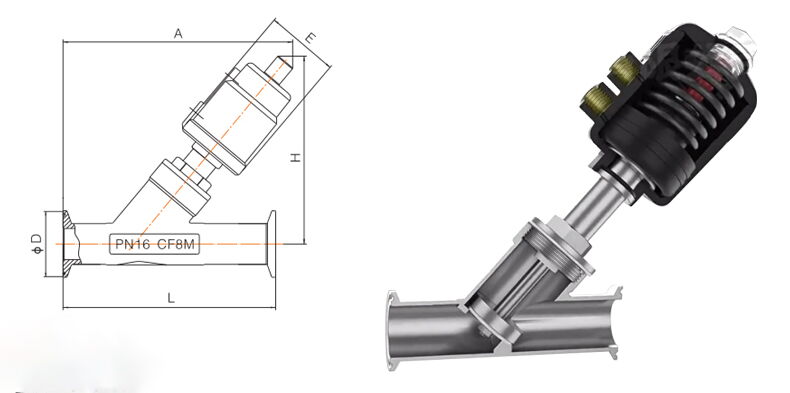

China Stainless Steel Angle Seat Valve Plant produces high-performance SS 304/SS 316 angle seat valves with pneumatic actuators for fast, automated flow control. Available in DN15-DN80 (1/2-3 Inches) sizes, these valves are rated for PN16/Class 150 LB and feature hygienic clamped ends for easy maintenance. Ideal for steam, water, and aggressive media in food & beverage, pharmaceutical, and chemical processing industries.

- Model No.: MV-20250714-ASV-01

- Hits: 17

- Categories: Low Emission Control Valves

- Tags: Pneumatic Actuated Angle Seat Valve, Stainless Steel Angle Seat Valve, SS 304 Angle Seat Valve

Detail Information

Product Name: Stainless Steel Angle Seat Valve

Size Range: DN15-DN80, 1/2-3 Inch

Pressure Range: 0-1.6Mpa, PN16, Class 150 LB

Body Material: Stainless Steel, SS 304, SS 316

Sealing Material: PTFE

Actuator Material: PA

Manufacturing Standard: GB, ISO, DIN

End Connection: Clamped

Actuation: Pneumatic Actuator

Medium Temperature: -10°C to +180°C

Ambient Temperature: -10°C to +60°C

Medium: Neutral Gas, Sir, Eater

Pneumatic Angle Seat Valve Applications

It is widely used in food and chemical processes, sterilizers, high-pressure disinfection washers, and dry washers for beer production lines. Compared to traditional angle seat valves, it has the following new features:

Visual position indicator for limit switch or emergency manual device.

Easy installation: The actuator can rotate 360°, and even the limit switch can rotate 360°. It can be easily installed in one or two limit switches.

Advanced pneumatic actuator: Made of engineering plastic exterior, safe and reliable. Low-friction piston structure, large capacity, low air consumption. Internal parts are self-lubricating, maintenance-free.

Multiple control methods: Normally open, normally closed, double action.

Smaller actuator required: When the fluid enters from the top of the valve stem, a smaller actuator can be used.

Easy connection: MAMUR standard connection, embedded metal joint.

Long life stem: The valve stem is made of PTEE (PTFE) seal, avoiding dirt entry. Self-lubricating, maintenance-free. The valve is specially processed to ensure precise positioning and can automatically adjust its position.

No water hammer effect: When the fluid enters from the bottom of the valve stem, the water hammer (water impact force) is absorbed.

Advanced valve mechanism: The flow rate is three times larger than that of a traditional angle seat valve, smaller size, better flow.

Angle Seat Valve Specifications

Widely used in: beer brewing, textile dyeing and bleaching, pharmaceutical and medical equipment, food processing, rubber machinery, organic or inorganic chemicals, high-temperature sterilization, water treatment.

Installation: Install according to requirements, preferably with the actuator facing up. If there is no position, other directions can also be chosen.

Features: Long life, maintenance-free, high reliability.

Medium temperature: -10°C to +180°C

Ambient temperature: -10°C to +60°C

Viscosity: Maximum 600 mm2/S

Control medium: Air or neutral gas control

Pressure range: 0.3-1MPA

Applicable medium: Water, neutral gas or liquid, alcohol, oil, organic solvents, steam, weak acid or alkali solution

Valve body material: Stainless steel 304

Valve core seal: PTFE

Stem seal: PIFE/FKM

Piston seal: FKM1NBR

Pneumatic Angle Seat Valve Options

Control functions: Normally open

PPS Actuator suitable for ambient temperature: -5°C to +130°C

Double acting actuators without spring return

Quick connection

Electronic position feedback

Independent adjustable stroke limit, suitable for low flow rate

Manual emergency switch

Pilot valve suitable for Namur adapter

Pneumatic Angle Seat Valve Data Parameters

|

Interface |

Inner Bore (mm) |

KV (m3/h) |

Max Working Pressure (bar) |

Required Air Pressure (bar) |

Actuator Size (mm) |

Flow Direction |

|

G3/8 |

10.0 |

3.7 |

0-16 |

4.0 |

50 |

Below the Seal |

|

G1/2 |

15.0 |

4.2 |

0-16 |

2.7 |

50 |

|

|

G1-1/4 |

20.0 |

6.0 |

0-16 |

2.0 |

63 |

|

|

G1 |

25.0 |

19.0 |

0-16 |

2.0 |

63 |

|

|

G1-1/4 |

32.0 |

27.5 |

0-16 |

2.0 |

63 |

|

|

G1-1/2 |

40.0 |

42.0 |

0-16 |

2.0 |

63 |

|

|

G2 |

50.0 |

52.0 |

0-16 |

2.0 |

80 |

|

|

G2-1/2 |

65.0 |

77.0 |

0-14 |

1.6 |

100 |

Dimensions

|

Size |

Actuator (mm) |

L |

D |

A |

H |

E |

|

DN15 |

Φ50 |

122 |

50.5 |

155 |

135 |

61 |

|

DN20 |

Φ50 |

139 |

50.5 |

155 |

140 |

61 |

|

DN25 |

Φ63 |

159 |

50.5 |

195 |

172 |

76 |

|

DN32 |

Φ63 |

176 |

64 |

205 |

175 |

76 |

|

DN40 |

Φ63 |

189 |

64 |

205 |

180 |

76 |

|

DN50 |

Φ80 |

208 |

77.5 |

245 |

205 |

95 |

|

DN65 |

Φ100 |

225 |

91 |

317 |

275 |

117 |

|

DN80 |

Φ100 |

255 |

106 |

342 |

290 |

117 |

Similar Products

ASTM A351 CF8M Angle Seat Valve, Stainless Steel, DN25, PN25

Pneumatic Angle Seat Valve, A351 CF8/CF8M, DN8-DN100, PN16/25

Top Guided Control Valve, 1/2-8 Inch, CL150-600, Unbalanced