(API 624 Additional High Temperature Version)

Key Specifications / Features

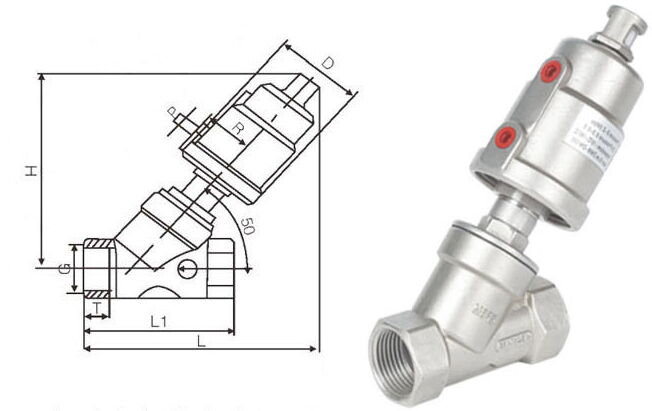

This pneumatic angle seat valve is constructed from stainless steel (ASTM A351 CF8 and CF8M grades) for enhanced durability and chemical resistance. Available in sizes ranging from DN8 to DN100 (1/4 inch to 4 inches) with threaded connections, it is rated for pressures of PN16 to PN25 (Class 150 to 300 LB). The valve features pneumatic actuation for rapid operation and precise flow control, making it suitable for steam, water, and aggressive media.

- Model No.: MV-20250711-ASV-01

- Hits: 17

- Categories: Low Emission Control Valves

- Tags: Pneumatic Actuated Angle Seat Valve, ASTM A351 CF8 Angle Seat Valve, ASTM A351 CF8M Angle Seat Valve

Detail Information

Product Name: Pneumatic Angle Seat Valve

Body Material: ASTM A351 CF8/CF8M

Nominal Diameter: DN8-DN100, 1/4-4 Inch

Nominal Pressure: PN16, PN25, Class 150-300 LB, 1.6/2.5Mpa

Connection Method: Threaded

Valve Core Seal: PTFE/PPL/PEEK/Metal Seal

Piston Seal: FKM/NBR

Valve Stem Seal: PTFE/PPL/FKM/Graphite

Medium Temperature: -10°C to 450°C (For high temperature and high pressure, please provide detailed working conditions for selection)

Control Pressure: 0.3-0.8Mpa

Applicable Medium: Water/Alcohol/Steam/Neutral Gases or Liquid Acid-Alkali Solutions, etc.

Installation Direction: Forward/Reverse (Install according to needs, try to make the actuator face up)

Applications of Pneumatic Angle Seat Valves

They are widely used in food and chemical processes, sterilizers, high-pressure disinfection washers, and dry washers in beer production lines. Compared to traditional angle seat valves, they have the following new features:

Visual position indicator for limit switch or emergency manual operation.

Easy installation: The pneumatic actuator can rotate 360°, and even the limit switch can rotate 360°. It is convenient to install one or two limit switches.

Advanced pneumatic actuator: With a thick engineering plastic shell, it is safe and reliable. The low-wear piston structure has a large capacity and low air consumption. The internal components are self-lubricating and maintenance-free.

Various control methods: Normally open, normally closed, and double acting.

Requires a smaller pneumatic actuator: When the fluid flows from the upper side of the valve stem, a smaller control head can be selected.

Easy connection: MAMUR standard connection, embedded metal joint.

Long life guide rod: The valve stem is sealed with PTEE to prevent dirt from entering. It is self-lubricating and maintenance-free. The valve stem is specially treated to ensure precise positioning and can automatically return to the correct position.

No water hammer effect: When the fluid flows from the lower side of the valve stem, the water hammer (water impact force) is absorbed.

Advanced valve body structure: The flow capacity is one-third larger than that of ordinary angle seat valves, with a smaller volume and better fluid dynamics.

Pneumatic Angle Seat Valve Dimension Table

|

Specification |

Actuator |

L1 |

L |

H |

D |

P |

Maximum Working Pressure (MPa) |

Air Source Pressure (MPa) |

|

DN15 |

50 |

68 |

140 |

135 |

62 |

G1/8 |

PN25 |

4-10P |

|

DN20 |

50 |

75 |

145 |

140 |

62 |

G1/8 |

||

|

DN25 |

50 |

90 |

155 |

145 |

62 |

G1/8 |

||

|

DN25 |

63 |

90 |

175 |

160 |

76 |

G1/8 |

||

|

DN32 |

63 |

115 |

193 |

175 |

76 |

G1/8 |

||

|

DN40 |

63 |

115 |

195 |

185 |

76 |

G1/8 |

||

|

DN50 |

63 |

135 |

205 |

200 |

76 |

G1/8 |

||

|

DN50 |

80 |

135 |

230 |

235 |

100 |

G1/8 |

Similar Products

ASTM A351 CF8M Angle Seat Valve, Stainless Steel, DN25, PN25

Stainless Steel Angle Seat Valve, DN15-DN80, PN16, Pneumatic

Top Guided Control Valve, 1/2-8 Inch, CL150-600, Unbalanced