(API 624 Additional High Temperature Version)

Key Specifications / Features

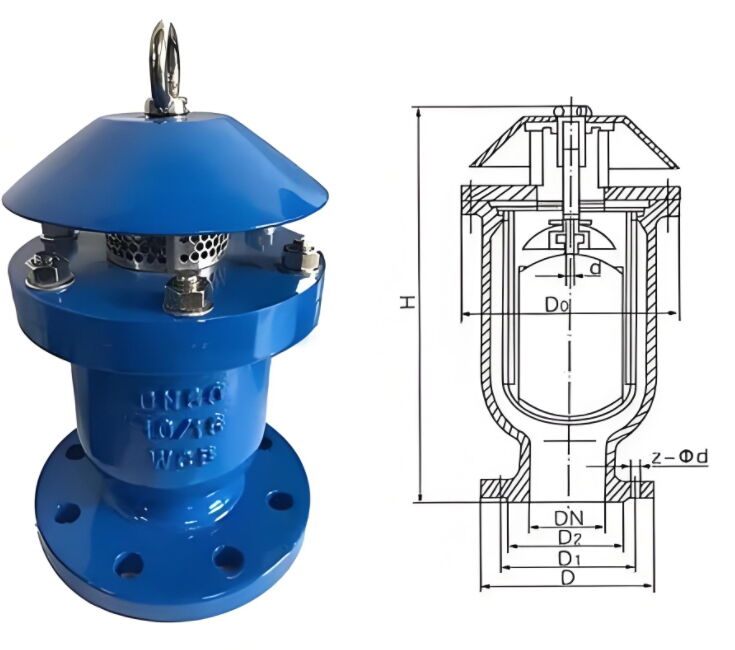

This quick air release valve is available in cast iron, carbon steel, stainless steel, and brass construction, with sizes ranging from DN50 to DN300 (2-12 inches) and pressure ratings of PN6-PN40 (Class 150-300 LB). Designed with flanged ends for secure installation, it efficiently removes trapped air from pipelines to prevent air pockets and maintain system efficiency. Suitable for water supply, irrigation, and industrial piping systems where automatic air venting is required to protect against pressure surges and ensure smooth fluid flow.

- Model No.: MV-20250711-ARV-01

- Hits: 20

- Categories: Low Emission Control Valves

- Tags: Cast Iron Air Release Valve, Quick Air Release Valve, Carbon Steel Air Release Valve

Detail Information

Product Name: Quick Air Release Valve

Diameter: DN50-DN300mm, 2-12 Inch

Pressure: PN6-PN40, 0.6-4.0Mpa, Class 150-300 LB

Standards: National, German, American, British, Russian, Japanese

Materials: Cast Iron, Carbon Steel, Stainless Steel, Brass, etc

Float Ball and Plug: Stainless Steel

Sealing Material: Nitrile Rubber

Valve Body Test Pressure: 1.5MPa

Float Ball and Sealing Test Pressure: 0.05-1.1MPA, No leakage

Temperature Range: 0°C to 70°C

Medium: Water

End Connection: Flanged

KP Type Air Release Valve Description

When the pipeline is in operation, the float ball rests at the bottom of the ball bowl, allowing for large volume air release. Once the air inside the pipe is exhausted, water rushes into the valve, causing the ball to react and float, closing the valve. During normal operation of the pipeline, if a small amount of gas accumulates to a certain level inside the valve, the water level inside the valve drops, causing the float ball to drop as well, allowing the gas to be expelled through the small holes. If the water pump stops, a negative pressure will occur, and the float ball will drop to ensure the safety of the pipeline by allowing a large volume of air intake.

Main Purpose of KP Type Air Release Valve

The KP-10 quick air release valve is suitable for industrial pipelines with water as the medium. It serves as a device for quickly removing air from the pipeline to improve the efficiency of water delivery equipment and protect the pipeline from deformation and cracking. It is an essential piece of equipment for pipelines. The valve is cylindrical in shape, with a stainless steel float ball and a plug inside. This valve is installed at the outlet of the pump or in the water supply pipeline to release a large amount of air trapped in the pipeline, thereby increasing the efficiency of water intake pipes and pumps. Once negative pressure occurs inside the pipe, this valve can quickly intake air to protect the pipeline from damage caused by negative pressure.

Main Features of KP Type Air Release Valve

It can remove air from the pipeline, reducing resistance and saving energy.

When there is negative pressure in the pipeline, this product can quickly and automatically intake air to prevent pipeline rupture.

Its air release capacity is several times that of ordinary dual-hole air release valves.

The float ball bracket is made of stainless steel.

|

Nominal Diameter (mm) |

D |

D1 |

D2 |

D3 |

H |

Z-φd |

|

25 |

115 |

85 |

65 |

140 |

285 |

4-14 |

|

50 |

160 |

125 |

102 |

160 |

340 |

4-14 |

|

80 |

195 |

160 |

135 |

205 |

490 |

4-18 |

|

100 |

215 |

180 |

158 |

240 |

545 |

8-18 |

|

150 |

280 |

240 |

212 |

300 |

615 |

8-23 |

|

200 |

335 |

295 |

268 |

380 |

730 |

8-23 |

KP Type Air Release Valve Air Release Volume per Hour Table

|

Specification |

25 |

50 |

80 |

100 |

150 |

200 |

|

Cubic Meters/Hour |

2-88 |

85-352 |

19-795 |

27-1145 |

41-1709 |

76-3179 |

Similar Products

Single Orifice Air Release Valve, Cast Iron, 1-8 Inch, CL150

Composite Air Release Valve, Ductile/Cast Iron, DN25-DN200

Top Guided Control Valve, 1/2-8 Inch, CL150-600, Unbalanced