(API 624 Additional High Temperature Version)

Key Specifications / Features

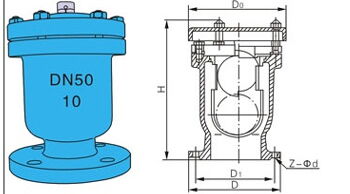

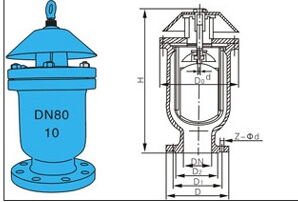

The Single Orifice Air Release Valve Factory offers a robust solution for air release in water systems. These valves feature a cast iron body, available in sizes ranging from DN25 to DN200 and 1 to 8 inches. They are rated for PN10 and PN16 pressures, as well as Class 150 LB, ensuring durability and reliability. Equipped with flanged end connections, these valves are specifically designed for use in water applications, providing efficient air release to maintain system performance and prevent damage.

- Model No.: MV-20250708-ARV-01

- Hits: 15

- Categories: Low Emission Control Valves

- Tags: Single Orifice Air Release Valve, Cast Iron Air Release Valve, Flanged Air Release Valve

Detail Information

Product Name: Single Orifice Air Release Valve

Body Material: Cast Iron

Size Range: DN25-DN200, 1-8 Inch

Pressure: PN10, PN16, Class 150 LB

End Connection: Flanged

Applicable Medium: Water

Operating Temperature: ≤100°C

Air Release Valve Air Volume Table: (Calculated at a flow rate of 1.5-3.0 meters per second)

|

Specification |

25 |

50 |

80 |

100 |

150 |

200 |

|

Cubic Meters/Hour |

4-8 |

11-22 |

22-40 |

42-60 |

61-122 |

83-166 |

Air Release Valve Connection Dimensions

|

Nominal Diameter (DN) |

D |

D1 |

D2 |

D3 |

H |

Z-Φd |

|

25 |

115 |

85 |

65 |

140 |

285 |

4-14 |

|

50 |

160 |

125 |

102 |

200 |

340 |

4-14 |

|

80 |

195 |

160 |

135 |

230 |

490 |

4-18 |

|

100 |

215 |

180 |

158 |

250 |

545 |

4-18 |

|

150 |

280 |

240 |

212 |

300 |

615 |

8-23 |

|

200 |

335 |

295 |

268 |

380 |

730 |

8-23 |

The air release valve is always open during normal operation, with the float repeatedly moving up and down to continuously release air. When maintenance or cleaning of the cavity is required, the valve should be closed.

Detailed Description of Flanged Single Orifice Air Release Valve

The flanged single orifice air release valve mainly consists of the valve body, valve door, cover, valve rod, float, and exhaust nozzle. It is used for small diameter pipes with a pipe size of φ50-200, and serves as an air release function for the pipeline, preventing blockages and air locks. If the water pump stops and negative pressure occurs in the pipeline, it can automatically suck in air to protect the pipeline safety.

Principle of Operation for Flanged Single Orifice Air Release Valve

When air needs to be released from the pipeline, the air inside the pipeline, under the pressure of water, enters the cavity through the exhaust nozzle. As the water in the pipeline fills the cavity, the float, under the influence of water buoyancy, moves upward to block the exhaust nozzle, achieving automatic sealing. Under normal conditions, the air inside the water is continuously expelled from the top of the cavity, causing the float to descend and leave the original sealing position. At this time, air is expelled through the exhaust nozzle again, and the float returns to its original position to automatically seal. Therefore, the air release valve remains open during normal operation, with the float repeatedly moving up and down to continuously release air. When maintenance or cleaning of the cavity is required, the valve should be closed.

Materials for Flanged Single Orifice Air Release Valve Components

Valve Body: Cast Iron

Valve Cover: Cast Iron

Float Ball: Stainless Steel

Plug: Rubber

Exhaust Nozzle: Brass

Screws, Nuts: Carbon Steel

Applications and Main Performance Specifications of Flanged Single Orifice Air Release Valve

The air release valve is suitable for water and hot water pipelines with a temperature not exceeding 100°C to expel all the air in the pipeline.

When installing a double outlet air release valve, a check valve (Q41F-16) must be installed at the bottom to verify water stoppage.

If the size of the air release valve flange needs to be changed according to the requirements, please specify the connection size in the contract.

Similar Products

Composite Air Release Valve, Ductile/Cast Iron, DN25-DN200

Quick Air Release Valve, Cast Iron, Carbon Steel, DN50-DN300

Top Guided Control Valve, 1/2-8 Inch, CL150-600, Unbalanced