(API 624 Additional High Temperature Version)

Key Specifications / Features

The Bellows Type Pressure Reducing Valve is a high-quality pressure control solution featuring a stainless steel SS 304 body and 10Cr18Ni9Ti bellows. Available in DN15, DN20, and DN25 sizes, as well as 1/2 to 1 inch, it is designed for applications requiring precise pressure regulation. The valve is rated for PN16 and 150 LB pressure, with threaded ends for easy installation. Its durable construction and reliable performance make it suitable for a wide range of industrial applications.

- Model No.: MV-20250708-PRV-01

- Hits: 22

- Categories: Low Emission Control Valves

- Tags: Bellows Type Pressure Reducing Valve, SS 304 Pressure Reducing Valve, PN16 Pressure Reducing Valve

Detail Information

Product Name: Bellows Type Pressure Reducing Valve

Body Material: Stainless Steel SS 304

Bellows Material: 10Cr18Ni9Ti

Size Range: DN15, DN20, DN25, 1/2 Inch, 3/4 Inch, 1 Inch

Pressure: PN16, Class 150 LB

End Connection: Threaded

Applicable Medium: Steam, Air, Liquid, etc

Operating Temperature: ≤180°C (with high-temperature type 250°C)

The bellows-type pressure reducing valve is a direct-acting bellows spring pressure reducing valve. It mainly consists of bellows, adjustment spring, valve seat, valve disc, and other components. It uses the pressure of the bellows to drive the valve disc, changing and controlling the opening degree of the valve to achieve the function of pressure reduction and stabilization. By adjusting the adjustment screw, the outlet pressure can be set.

Structural Features

Compact size, light weight. The pressure detection device uses bellows, which have good durability. Pressure can be adjusted by simply turning a plastic wheel, without the need for tools. It is equipped with a built-in filter screen to protect the valve's performance from dust and impurities. The body cavity is assembled with a valve disc, valve body seal ring, and auxiliary spring; the auxiliary spring ensures automatic sealing of the valve disc and valve body seal ring. The outlet body cavity is equipped with an elastic sealing element (bellows) to compensate for the leakage of the medium pressure and the uneven pressure distribution. The screw is used to adjust the spring load pressure to improve the working performance of the pressure reducing valve.

Design Advantages

- Small size, lightweight.

- The pressure detection device uses bellows, which have good durability.

- Pressure can be adjusted by simply turning a plastic wheel, without the need for tools.

- Equipped with an internal filter screen to protect the valve's performance from dust and impurities.

- The diaphragm-type pressure reducing valve uses internal threading for connection, making installation convenient.

- Both the valve body and valve seat are made of stainless steel, ensuring a long service life.

Bellows Type Pressure Reducing Valve

Product Model: Y14H-16P, DN15, DN20, DN25

The interior of the bellows type pressure reducing valve is made of stainless steel bellows, which is simple and durable, suitable for applications requiring high sensitivity and precise installation space. The connection method is internal threading, with common specifications including G1/2, G3/4 PN1.6MPa.

Features and Advantages of Pressure Reducing Valve Structure

The pressure reducing valve is mainly composed of valve seat, valve disc, bellows, and spring components. It sets the outlet pressure by adjusting the spring, and when the outlet pressure decreases, the valve opens more; when the outlet pressure reaches the preset value, the valve opening decreases, mainly achieving pressure reduction and stabilization through the action of the diaphragm's surface area on the medium pressure in the bellows and the action of the spring's adjustment. The use of a plastic wheel for pressure adjustment is convenient, requiring no tools. The internal structure uses bellows, and the seal surface is protected by a filter screen, which is not easily damaged, greatly extending the service life.

Main Technical Parameters and Performance Indicators of Bellows Pressure Reducing Valve

- Rated Pressure: 1.6 MPa

- Shell Test Pressure: 2.4 MPa

- Seal Test Pressure: 1.76 MPa

- Maximum Inlet Pressure: 1.6 MPa

- Outlet Pressure Range: 0.05-1.0 MPa

- Pressure Characteristic Deviation (MPa): △P2P GB 12244-1989

- Flow Characteristic Deviation (MPa): △P2P GB 12244-1989

- Minimum Pressure Difference: 0.15 MPa

- Leakage: GB 12244-1989

- Applicable Medium: Steam, Air, Liquid

- Operating Temperature: ≤180°C (with high-temperature type 250°C)

- Note: The shell test does not include the bellows; the shell pressure test must be conducted after removing the bellows components.

Main Component Materials of Bellows Type Pressure Reducing Valve

|

Part Name |

Material |

|

Valve Body, Base Cover |

Stainless Steel 304 |

|

Valve Cover |

Cast Aluminum Alloy/CF8 |

|

Valve Stem |

2Cr13 |

|

Valve Seat |

2Cr13 |

|

Valve Ball |

2Cr13 |

|

Bellows |

10Cr18Ni9Ti |

|

Handwheel |

Heat-resistant Plastic |

|

Main Spring |

50CrVA |

|

Adjustment Spring |

60Si2Mn |

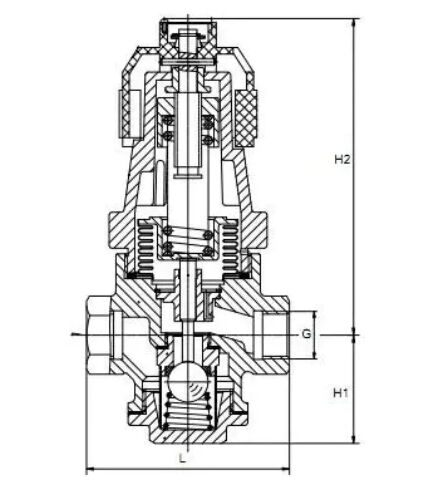

Main Connection Dimensions of Pressure Reducing Valve

|

Diameter |

L |

H |

H1 |

G |

|

DN15 |

85 |

140 |

52 |

1/2 Inch |

|

DN20 |

95 |

143 |

55 |

3/4 Inch |

|

DN25 |

105 |

146 |

58 |

1 Inch |

Threaded Pipe Fitting Size Chart

|

Nominal Diameter |

Size |

External Thread Diameter |

Internal Thread Diameter |

|

DN6 |

1/8 Inch |

9.5mm |

8.5mm |

|

DN8 |

1/4 Inch |

12.5mm |

11.5mm |

|

DN10 |

3/8 Inch |

16mm |

15mm |

|

DN15 |

1/2 Inch |

20mm |

19mm |

|

DN20 |

3/4 Inch |

25.5mm |

24mm |

|

DN25 |

1 Inch |

32mm |

30mm |

|

DN32 |

1-1/4 Inch |

40.5mm |

39mm |

|

DN40 |

1-1/2 Inch |

46mm |

44mm |

|

DN50 |

2 Inch |

58mm |

56.5mm |

|

DN65 |

2-1/2 Inch |

74mm |

72.5mm |

|

DN80 |

3 Inch |

86mm |

84.5mm |

|

DN100 |

4 Inch |

112mm |

110mm |

Similar Products

Stainless Steel Pressure Reducing Valve, SS 304/316, 1/2-2 IN

Top Guided Control Valve, 1/2-8 Inch, CL150-600, Unbalanced

Cage Guided Control Valve, CS, SS, AS, 1.5-24 IN, Single Seat