(API 624 Additional High Temperature Version)

Key Specifications / Features

This custom manual pinch valve is available in multiple materials, including stainless steel, carbon steel, cast iron, aluminum alloy, and plastic, catering to diverse industrial needs. Sizes range from DN25 to DN300 (1-12 inch), with pressure ratings of PN6 and PN4. It features a durable natural rubber sleeve for excellent abrasion and chemical resistance, ensuring reliable flow control for slurry, abrasive, and corrosive media in mining, wastewater, and process industries.

- Model No.: MV-20250711-PV-01

- Hits: 11

- Categories: Low Emission Control Valves

- Tags: Manual Pinch Valve, Stainless Steel Pinch Valve, Carbon Steel Pinch Valve

Detail Information

Product Name: Manual Pinch Valve

Design and Manufacturing Standard: MFG

Size Range: DN25-DN300, 1-12 Inch

Pressure Rating: PN6, PN4, Class 150 LB

Body Materials: Stainless Steel, Carbon Steel, Cast Iron, Aluminum Alloy, Plastic

Sleeve Materials: Natural Rubber

End Connection: Flanged

Operation: Manual

Medium: Slurry, Abrasive, Dust

What is Manual Pinch Valve?

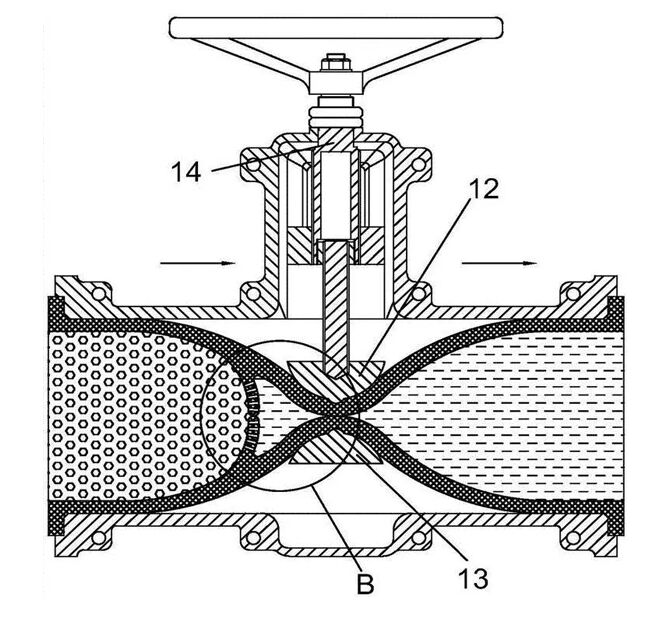

Also known as a manual pinch valve, it is composed of a rubber hose, a small valve rod, upper and lower valve plates, a lever, a support frame, and handwheel components. It is designed to be corrosion-resistant, frost-resistant, and has good sealing performance. Simply replacing the rubber hose can restore the valve to its original condition, extending its lifespan to 4-6 times that of a standard valve. The drive methods include manual, pneumatic, electric, and various other options, and it can also be customized to meet specific customer requirements.

The manual pinch valve has a fixed position on the hose clamp, ensuring that the inner lining remains in place even after long periods of closure, allowing it to return to its original position and achieve full flow or full cut. The manual pinch valve is more suitable for adjusting the flow of fluids and can also be operated manually or with a handwheel for convenient selection of different drivers.

The valve is a full-bore valve with no gaps, and the tight parts or seats do not affect the operation of the valve. As shown in the figure, when abrasive particles hit the synthetic rubber surface, they are first absorbed and then bounce back. The elasticity and toughness of the synthetic rubber hose are much better than those of metal valves. The fatigue life of the rubber hose during the dynamic fatigue process under cyclic loads is also different. Research on NR rubber indicates that when the load ratio R (R is the ratio of the minimum load to the maximum load) increases, although the energy input decreases, the fatigue life of the sample increases. When R is negative, especially when R=-1, this corresponds to symmetrical tensile/compressive cyclic loading, and fatigue cracks will increase, and crystallization will not occur because crystallization occurs during the relaxation phase. At high load ratios (R=0.5), rubber crystallization occurs at the crack tip due to stress concentration or plastic deformation, preventing crack propagation.

For various loads and complex load situations, the fatigue life is more complex. Under tensile/compressive, tensile/stretch, and tensile/any cyclic loading conditions, the stress amplitude is not constant, and the loading sequence also greatly affects fatigue life. From low to high loads, fatigue life is much longer than from high to low loads. The degree of change in fatigue life reflects the tensile and compressive properties of the rubber hose, with higher tensile strength and lower compressive strength. The tensile fatigue life of the rubber hose is longer than its compressive fatigue life. The method for testing the fatigue life of the rubber hose is to first conduct a certain period of tensile fatigue test, then conduct a tensile and compression fatigue test, and finally measure the stress-strain curve on an electronic tensile testing machine to determine the tensile and compressive fatigue life of the rubber hose.

Manual Natural Rubber Pinch Valve Main Connection Dimensions

|

Nominal Diameter (DN) |

Nominal Pressure (MPa) |

Working Pressure (MPa) |

L |

L1 |

D |

D1 |

Z-Φ |

H |

A |

|

25 |

0.6 |

0.6 |

160 |

124 |

115 |

85 |

4-14 |

||

|

32 |

165 |

145 |

140 |

100 |

4-18 |

||||

|

40 |

190 |

157 |

150 |

110 |

4-18 |

||||

|

50 |

210 |

160 |

160 |

125 |

4-18 |

||||

|

65 |

250 |

199 |

180 |

145 |

4-18 |

||||

|

80 |

300 |

222 |

195 |

160 |

4-18 |

||||

|

100 |

350 |

250 |

215 |

180 |

8-18 |

||||

|

125 |

430 |

318 |

245 |

210 |

8-18 |

||||

|

150 |

500 |

350 |

280 |

240 |

8-23 |

1000 |

265 |

||

|

200 |

0.4 |

0.4 |

650 |

446 |

335 |

295 |

8-23 |

1174 |

330 |

|

250 |

800 |

516 |

395 |

350 |

12-23 |

||||

|

300 |

950 |

562 |

445 |

400 |

12-23 |

Rubber Lining Material and Usage Range

|

Lining Material |

Applicable Temperature |

Applicable Medium |

|

Hard Rubber (NR) |

-10°C to 85°C |

Resistant to strong acids (except concentrated nitric acid, chromic acid, and oxidizing acids) and organic solvents, suitable for: hydrogen chloride, sulfur dioxide, acetic acid, formic acid, 30% sulfuric acid, 50% phosphoric acid, 80% nitric acid, alkalis, salts, heavy metal salts, hydrogen peroxide, ammonia water, brine, hydrogen sulfide, sodium hypochlorite, sodium hydroxide, ammonia water, organic acids, alcohols, etc. |

|

Soft Rubber (BR) |

-10°C to 80°C |

Good resistance to acids. Mainly used for sulfuric acid with a concentration below 50%, hydrochloric acid, sodium hydroxide, ammonia water, neutral salt solution and alkaline salt solution, coal tar, coal tar pitch, and various non-corrosive slurries. |

|

Butyl Rubber (IR) |

10°C to 120°C |

Anti-aging, anti-oxidation, can withstand a large number of acids, alkalis and oxidizing agents, suitable for: salt water, organic acids, inorganic acids, oxygen, chlorine, alcohols, fats, etc. <30% sulfuric acid, nitric acid, hydrochloric acid, coal tar oil, animal oil, vegetable oil, synthetic oil and various alkalis. |

|

Chloroprene Rubber |

-10°C to 105°C |

Suitable for animal oil, vegetable oil and non-corrosive mineral oils with large pH value changes, resistant to wear. |

Fluoroplastic and Lining Material and Usage Range

|

Lining Material (Code) |

Applicable Temperature |

Applicable Medium |

|

Polytetrafluoroethylene (FEP) |

≤120°C |

Various concentrations of hydrochloric acid, sulfuric acid, nitric acid, and organic acids, strong oxidizing agents, various organic solvents and strong alkalis, suitable for: various organic solvents and strong alkalis, metal plating and pickling solutions, elements and their compounds, and other strong oxidizing agents. |

|

Polyvinylidene Fluoride (PVDF) |

≤100°C |

|

|

Perfluoroalkoxy (PFA) |

≤180°C |

|

|

Polytetrafluoroethylene (PTFE) |

≤180°C |

|

|

Perfluorinated Methyl (PFA) |

≤180°C |

|

|

Polyphenylene Sulfide (PPS) |

≤100°C |

Except for nitric acid, chloric acid, and strong oxidizing agents, suitable for most organic acids, inorganic acids, and inorganic solvents. |

|

Polysulfide Rubber |

≤100°C |

Except for hydrochloric acid, concentrated sulfuric acid, strong alkalis, and other general corrosive media. |

Rubber Material and Usage Range

|

Rubber Name and Code |

Applicable Temperature |

Applicable Medium |

|

Butyl Rubber (B Grade) (IR) |

≤120°C |

85% nitric acid, hydrochloric acid, sulfuric acid, phosphoric acid, potassium permanganate and various organic solvents. |

|

Natural Rubber (NR) |

≤80°C |

Purified water, salt water, dilute inorganic acids. |

|

Polydimethylsiloxane (PDM) |

≤120°C |

Has the same resistance to alkalis as natural rubber, suitable for low-pressure steam, hot water, and other media with good performance. |

|

Chloroprene Rubber (CR) |

≤100°C |

Resistant to acids, alkalis, oil and non-corrosive solvents, with better resistance than natural rubber. |

|

Nitrile Rubber (NBR) |

≤100°C |

Oil-resistant, similar to natural rubber in terms of resistance to acids and alkalis. |

|

Fluorosilicone Rubber (FPM) |

≤230°C |

Has the same resistance to acids as fluoroplastic, suitable for strong acids, strong alkalis, and other media. |

|

High Temperature Silicone (Silicone) |

≤240°C |

Resistant to oil, aging, high temperature, and has excellent sealing performance. |

Similar Products

Top Guided Control Valve, 1/2-8 Inch, CL150-600, Unbalanced

Cage Guided Control Valve, CS, SS, AS, 1.5-24 IN, Single Seat

Pneumatic Single Seated Control Valve, A351 CF8, DN80, PN16