(API 624 Additional High Temperature Version)

Key Specifications / Features

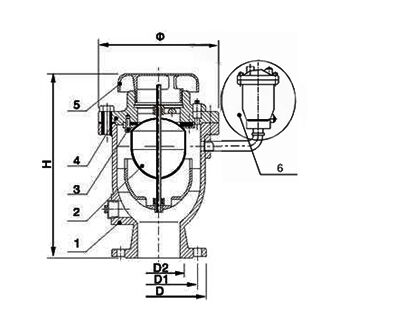

This high-speed air release valve, available from a leading supplier, is engineered for efficient air discharge in pipelines to prevent vacuum formation and ensure optimal flow. Constructed from durable materials including ASTM A216 WCB and QT450, it offers excellent corrosion resistance and long service life. Suitable for a wide range of applications, the valve comes in sizes from DN50 to DN300 (2 to 12 inches) and is rated for PN10, PN16, and Class 150 LB pressure standards.

- Model No.: MV-20250709-ARV-01

- Hits: 8

- Categories: Low Emission Control Valves

- Tags: Composite Air Release Valve, High-speed Air Release Valve, ASTM A216 WCB Air Release Valve

Detail Information

Product Name: Composite High-speed Air Release Valve

Body Material: ASTM A216 WCB, QT450

Size Range: DN50-DN300, 2-12 Inch

Pressure: PN10, PN16, Class 150 LB

End Connection: Flanged Ends

Applicable Medium: Water

Roller Shutter Type Composite Air Release Valve, Rapid Automatic Air Intake & Exhaust Valve

Product Description

The composite high-speed air intake and exhaust valve prevents the float ball from being blown up and blocking the exhaust port under high-speed airflow, which could cause the valve to fail. To avoid blockage of the valve port, traditional high-speed air valves use a protective sleeve at the inlet, making their structure more complex.

Product Features

High-speed air exhaust during filling, resistant to blockage.

High-speed air intake during draining.

Micro air exhaust under normal pressure.

Working Principle

The composite high-speed air intake and exhaust valve is a float-type air valve manufactured using Bernoulli’s theory. It remains fully open under airflow, and when a solid water column rises, the float ball is immediately lifted to tightly seal the exhaust port. The valve uses a specifically sized float ball, so that the aerodynamic force generated can keep the float ball open (suspended) when airflow passes through, while the buoyancy produced by the rising water column lifts it. Combined with a conical inlet at an appropriate angle, this ensures that no matter how high the air pressure or airflow velocity, the exhaust port will not be blocked.

|

Nominal Diameter (DN) |

Length A (mm) |

Width B/L (mm) |

Height H (mm) |

Outer Diameter D (mm) |

Bolt Circle Diameter (mm) |

Flange Thickness (mm) |

Bolt Holes |

|

DN50 |

250 |

130 |

260 |

165 |

125 |

19 |

4-19 |

|

DN80 |

315 |

170 |

340 |

200 |

160 |

19 |

8-19 |

|

DN100 |

413 |

334 |

220 |

180 |

19 |

8-19 |

|

|

DN150 |

580 |

520 |

285 |

240 |

19 |

8-23 |

|

|

DN200 |

668 |

640 |

340 |

295 |

22 |

8-23 |

|

|

DN250 |

770 |

780 |

395 |

350 |

22 |

12-23 |

|

|

DN300 |

850 |

920 |

445 |

400 |

24.5 |

12-23 |

Installation Requirements

1. Before installation, inspect and remove any debris inside the valve body.

2. Install a gate valve in front of the air valve to facilitate future installation and maintenance. If the valve is installed in a manhole, ensure there is sufficient space for technicians to perform adjustments and maintenance.

3. If the air valve is installed outdoors, ensure proper insulation to prevent water inside the valve from freezing and damaging the valve.

4. If the pipeline experiences frequent water supply interruptions, it is recommended to install a buffer valve in front of the air valve.

5. Common installation locations for the composite high-speed air valve include: local high points, points where the downward slope increases, points where the upward slope decreases, and long pipe sections with continuous upward or downward slopes without bends.

Selection of Installation Location

The installation location of the air valve directly affects its performance and the operating condition of the pipeline. Designers often focus only on local high points, but there are various suitable locations for air valve installation. Only by considering the entire pipeline system comprehensively can optimal air release be achieved. Common installation locations include: local high points, points where the downward slope increases, points where the upward slope decreases, and long pipe sections with continuous upward or downward slopes without bends.

Similar Products

Composite Air Release Valve, Ductile/Cast Iron, DN25-DN200

Top Guided Control Valve, 1/2-8 Inch, CL150-600, Unbalanced

Cage Guided Control Valve, CS, SS, AS, 1.5-24 IN, Single Seat