(API 624 Additional High Temperature Version)

Key Specifications / Features

The China Fluorine-lined Ball Valves Factory offers high-quality ball valves designed to meet stringent industry standards. These valves feature a cast carbon steel body (ASTM A216 WCB) and are manufactured in compliance with ASME B16.34. With a nominal diameter of DN32 (1-1/4 inch) and a pressure rating of PN16 (Class 150 LB), they are equipped with RF flanged ends for secure and reliable connections. The fluorine lining ensures excellent chemical resistance and durability, making these valves ideal for applications in various industrial settings.

- Model No.: MV-20250630-LTMSBV-02

- Hits: 2

- Categories: Low Torque Metal Seated Ball Valve

- Tags: ASTM A216 WCB Ball Valve, Fluorine-lined Ball Valve, DN32 Ball Valve

Detail Information

Product Name: Fluorine-lined Ball Valves

Design Standard: ASME B16.34

Body Material: ASTM A216 WCB

Lining Material: Fluorine

Size: DN32, 1-1/4 Inch

Pressure: PN16, Class 150 LB

Operation: Lever

End Connection: RF Flanged

Face to Face Standard: ASME B16.10

Test & Inspection Standard: API 598

Certificates: TA-Luft, ISO 15848-1, API 622, ect

Product Specifications for Fluorine-Lined Ball Valves

Body Material: HT250, ASTM A216 WCB, A351 CF8, CF8M, CF3, CF3M

Design Standard: GB 12237

Structural Length: GB 12221

Flange Standard: JB/T 79-94, GB/T 9113.1-26

Inspection and Test: JB/T 9092-99

Driving Method: Manual, Electric, Pneumatic, Worm Gear

Manual Fluorine-Lined Ball Valve Product Features

The basic series of manual fluorine-lined ball valves is Q41F46 type. In addition to having low fluid resistance, fast opening and closing speed, and simple structure, it also has the following advantages.

1. The ball valve with FEP lining has extremely high chemical stability and can be used for any strong corrosive substances except "molten alkali metals and elemental fluorine".

2. The full bore, floating ball structure allows the valve to close without leakage across the entire pressure range, facilitating pipeline system pigging and maintenance.

3. The closure member, the ball, is cast (forged) as one piece with the valve stem, eliminating the possibility of the valve stem being forced out of the pressure-bearing component due to pressure changes, fundamentally ensuring the safety of use in engineering.

4. The structure is compact and reasonable, with the minimum internal cavity space in the valve body, reducing medium retention. In addition, the special molding process ensures good density of the sealing surface, coupled with a chevron-shaped PTFE packing combination, achieving zero leakage of the valve.

5. The two-piece and three-piece structures can adapt to various pipeline systems and working conditions. The three-piece ball valve allows the main valve body to be separated from the side valve bodies, enabling online quick replacement and maintenance.

Manual Fluorine-Lined Ball Valve Main Materials

|

Part Name |

Gray Cast Iron |

Cast Steel |

Stainless Steel |

Ultra-low Carbon Stainless Steel |

||

|

Z |

C |

P |

R |

PL |

RL |

|

|

Valve Body/Cover |

HT250 |

WCB |

CF8 |

CF8M |

CF3 |

CF3M |

|

Ball |

WCB |

WCB |

CF8 |

CF8M |

CF3 |

CF3M |

|

Lining/Seat |

FEP (F46), PCTFE (F3), PFA |

|||||

|

Packing Cover |

HT250 |

WCB |

CF8 |

CF8M |

CF3 |

CF3M |

|

Packing |

PTFE (F4) |

|||||

|

Bolt |

35 |

35 |

1Cr17Ni2 |

1Cr17Ni2 |

1Cr18Ni9 |

1Cr18Ni9 |

|

Nut |

45 |

45 |

0Cr18Ni9 |

0Cr18Ni9 |

0Cr18Ni9 |

0Cr18Ni9 |

|

Handle |

WCC |

WCC |

WCC |

WCC |

WCC |

WCC |

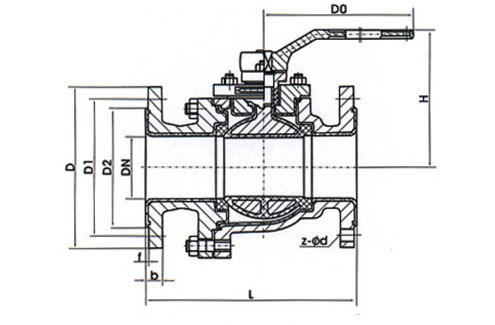

Manual Fluorine-Lined Ball Valve Main Dimensions

|

Nominal Diameter DN (mm) |

NPS (inch) |

L |

D |

D1 |

D2 |

f |

b |

Z-ød |

Do (Lever) |

Do (Gear) |

H |

WT (Kg) |

|

15 |

1/2 |

140 |

95 |

65 |

45 |

2 |

14 |

4-ø14 |

120 |

80 |

2.5 |

|

|

20 |

3/4 |

140 |

105 |

75 |

55 |

2 |

16 |

4-ø14 |

140 |

90 |

3 |

|

|

25 |

1 |

150 |

115 |

85 |

65 |

2 |

16 |

4-ø14 |

160 |

100 |

4.5 |

|

|

32 |

1/4 |

165 |

135 |

100 |

78 |

2 |

18 |

4-ø14 |

160 |

110 |

5.7 |

|

|

40 |

1/2 |

180 |

145 |

110 |

85 |

2 |

18 |

4-ø14 |

200 |

120 |

7 |

|

|

50 |

2 |

200 |

160 |

125 |

100 |

3 |

20 |

4-ø14 |

250 |

135 |

9.5 |

|

|

65 |

1/2 |

220 |

180 |

145 |

120 |

3 |

20 |

4-ø14 |

300 |

145 |

15 |

|

|

80 |

3 |

250 |

195 |

160 |

135 |

3 |

22 |

4-ø14 |

350 |

185 |

19 |

|

|

100 |

4 |

280 |

215 |

180 |

155 |

3 |

22 |

8-ø18 |

400 |

95 |

33 |

|

|

125 |

5 |

320 |

245 |

210 |

185 |

3 |

24 |

8-ø18 |

500 |

210 |

58 |

|

|

150 |

6 |

360 |

280 |

240 |

210 |

3 |

24 |

8-ø23 |

200 |

450 |

93 |

|

|

200 |

8 |

457 |

335 |

295 |

265 |

3 |

26 |

8-ø23 |

240 |

490 |

155 |

|

|

250 |

10 |

533 |

390 |

350 |

320 |

3 |

28 |

12-ø23 |

240 |

550 |

210 |

Similar Products

Fluorine-lined Ball Valve, API 608, ASTM A216 WCB, DN300, RF

Pneumatic Actuated Ball Valves, BS 5351, DN80, PN16, 3 Inch

Pneumatic Actuated 3-Way Ball Valve, 1/2-8 Inch, 150/300 LB