(API 624 Additional High Temperature Version)

Key Specifications / Features

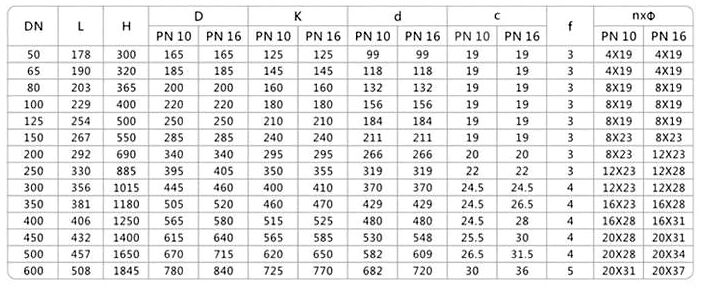

The Grooved Silent Check Valve Manufacturer specializes in producing high-quality grooved silent check valves suitable for firefighting systems. These valves are made from durable materials such as ductile iron and carbon steel, ensuring robustness and reliability. They are available in sizes ranging from DN50 to DN600 (2 to 24 inches) and can handle pressure ratings of PN10 and PN16, as well as Class 150 LB. The valves feature flanged ends for easy installation and integration into existing piping systems.

- Model No.: MV-20250701-CSCV-03

- Hits: 7

- Categories: Cast Steel Check Valve

- Tags: Ductile Iron Check Valve, Silent Check Valve, Grooved Check Valve

Detail Information

Product Name: Grooved Silent Check Valve

Product Model: HC81X

Material: Ductile Iron, Carbon Steel

Size Range: DN50-DN600, 2-24 Inch

Pressure: PN10, PN16, Class 150 LB

Connection Type: Grooved

Applicable Medium: Water/Non-corrosive Medium

Operating Temperature: ≤85°C

The grooved check valve is used in fire protection pipelines and connects via grooved couplings. The silent check valve is suitable for water supply and drainage pipelines. The valve flap uses a central axis guide from both import ends, which allows for flexible operation and can be installed horizontally or vertically. The valve flap uses a spring, and its rapid closure can eliminate water hammer, with good sealing performance. It has the advantages of small size, light weight, low fluid resistance, wear resistance, and long lifespan. The grooved check valve is installed in water supply and drainage, fire protection, and heating systems, and is also used at the outlet of water pumps to prevent backflow from damaging the pump.