(API 624 Additional High Temperature Version)

Key Specifications / Features

The China Slow Closing Silent Check Valve Supplier offers a high-quality valve with a Ductile Iron QT450 body, ensuring strength and durability. This valve features a DN150 (6 Inch) size and a pressure rating of PN16 (Pressure Class 150 LB). It is designed with hydraulic control for smooth operation and comes with flanged ends for easy installation. The slow closing mechanism reduces water hammer effects, making it ideal for maintaining system stability and reducing noise.

- Model No.: MV-20250704-CSCV-01

- Hits: 22

- Categories: Cast Steel Check Valve

- Tags: Silent Check Valve, QT450 Check Valve, Slow Closing Check Valve

Detail Information

Product Name: Slow Closing Silent Check Valve

Body Material: Ductile Iron QT450

Size: DN150, 6 Inch

Pressure: PN16, Class 150 LB

End Connection: Flanged

Operation: Hydraulic Control

Components: Main Valve, One-way Valve, Needle Valve, Micro-filter, Pressure Gauge

Product Range

Pressure: Class 125 LB, 150 LB, 300 LB, PN10, PN16, PN25

Size: 3/4-24 Inch (DN20-DN600)

Materials: Cast Iron, Ductile Iron

Working Temperature: 0°C to +80°C

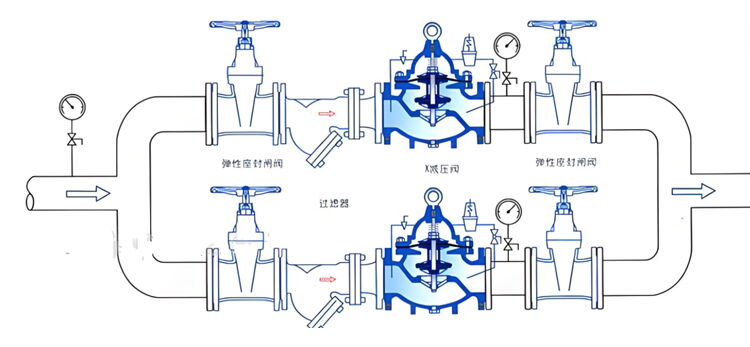

The slow-closing check valve is installed in the water supply system of high-rise buildings and other water supply systems at the water pump outlet to prevent backflow, water hammer, and water impact phenomena. This valve integrates the functions of an electric valve, check valve, and water hammer eliminator, effectively enhancing the safety of the water supply system. It integrates the principles of delay opening, speed, and slow closing to eliminate water hammer, preventing the occurrence of pump water hammer and pump stoppage water hammer.

Slow Closing Check Valve Working Principle

When the valve is supplied with water from the water inlet, water passes through a micro-filter, needle valve, and one-way valve into the main valve control chamber, then through the ball valve to the downstream. Since the needle valve opening is smaller than the ball valve opening, the water discharge speed from the main valve control chamber is greater than the water intake speed, thus reducing the pressure in the control chamber, which opens the main valve to supply water downstream.

When the pipeline stops supplying water, if the downstream begins to backflow, some of the backflow enters the main valve control chamber through the ball valve. Due to the one-way valve action, the backflow cannot flow out from the main control chamber, causing the control chamber to gradually pressurize and slowly close the main valve.

Slow Closing Check Valve Structural Features

The slow-closing check valve consists of a main valve, one-way valve, needle valve, micro-filter, and pressure gauge, forming a hydraulic control system. It uses hydraulic power for automatic operation, allowing the main valve to open or close at a controlled speed. It prevents the occurrence of water impact to achieve the effect of noise reduction during slow closing.

This product uses hydraulic power for automatic control, requiring no additional equipment or energy, making it easy to maintain, and ensuring stable opening and closing.

This series of valves is widely used in high-rise buildings, residential areas, and other water supply network systems as well as urban water supply projects.

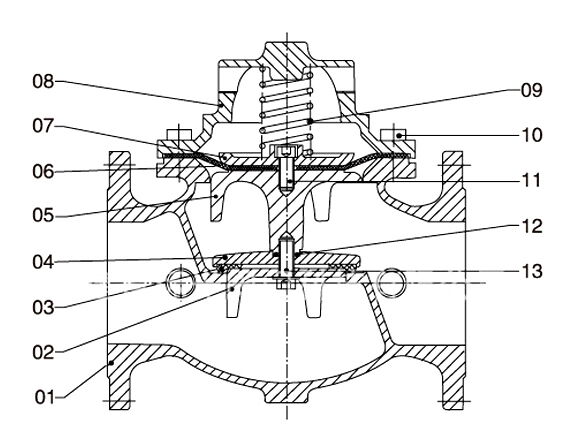

01. Valve Body

02. Guiding Valve Disc

03. Valve Disc Sealing Ring

04. Main Valve Disc

05. Main Guiding Valve Disc

06. Diaphragm

07. Diaphragm Pressure Plate

08. Cover

09. Spring

10. Bolt

11. Hexagonal Socket Screw

12. "O" Ring

13. Hexagonal Nut

Slow Closing Silent Check Valve Dimension Table

|

Nominal Diameter DN (mm) |

Length L (mm) |

A1 (mm) |

A (mm) |

H1 (mm) |

H (mm) |

F (mm) |

|

20 |

150 |

130 |

325 |

179 |

212 |

116 |

|

25 |

160 |

130 |

325 |

179 |

212 |

116 |

|

32 |

180 |

130 |

325 |

179 |

212 |

116 |

|

40 |

200 |

140 |

335 |

210 |

265 |

168 |

|

50 |

203 |

140 |

335 |

210 |

265 |

168 |

|

65 |

215 |

140 |

335 |

215 |

310 |

180 |

|

80 |

241 |

145 |

345 |

245 |

350 |

210 |

|

100 |

270 |

155 |

365 |

305 |

460 |

284 |

|

125 |

300 |

165 |

385 |

365 |

520 |

310 |

|

150 |

330 |

180 |

410 |

415 |

570 |

370 |

|

200 |

400 |

205 |

465 |

510 |

840 |

463 |

|

250 |

480 |

225 |

505 |

560 |

890 |

525 |

|

300 |

550 |

245 |

545 |

658 |

1030 |

625 |

|

350 |

622 |

275 |

595 |

696 |

1090 |

705 |

|

400 |

685 |

285 |

625 |

735 |

1150 |

778 |

|

450 |

750 |

285 |

625 |

735 |

1150 |

778 |

|

500 |

811 |

410 |

780 |

750 |

1110 |

690 |

|

600 |

935 |

456 |

888 |

850 |

1286 |

785 |