(API 624 Additional High Temperature Version)

Key Specifications / Features

The Slow-closing Butterfly Check Valve Factory produces robust check valves with a ductile iron QT450 body, designed for DN100 (4 inch) size and PN16/Class 150 LB pressure ratings. These valves feature flanged ends for secure installation and are available in cast iron or stainless steel options, ensuring durability and reliability in various piping systems.

- Model No.: MV-20250701-CSCV-01

- Hits: 22

- Categories: Cast Steel Check Valve

- Tags: Butterfly Check Valve, Slow Closing Check Valve, Ductile Iron Check Valve

Detail Information

Product Name: Micro-Resistance Slow-closing Butterfly Check Valve

Body Material: Ductile Iron QT450

Size: DN100, 4 Inch

Pressure: PN16, Class 150 LB

End Connection: Flanged

Product Range

Product Models: HH48X/H, HH49X/H, HH46X/H

Nominal Diameter: DN40-DN800, 1-1/2 Inch to 32 Inch

Pressure Range: 1.0-2.5 MPa, PN10, PN16, PN25, Class 150-300 LB

Body Material: Cast Iron, Ductile Iron, Cast Steel, Stainless Steel

Technical Specifications for Micro-Resistance Slow-Closing Butterfly Check Valve

|

Model |

Nominal Pressure |

Strength Test Pressure |

Sealing Pressure |

Applicable Temperature |

Applicable Medium |

Slow-Closing Time |

|

HH46X |

1.0MPa |

1.5MPa |

1.1MPa |

≤80°C |

Seawater |

≤60 seconds |

|

HH48X |

1.6MPa |

2.4MPa |

1.76MPa |

Sewage Water |

||

|

HH49X |

2.5MPa |

3.75MPa |

2.75MPa |

Fresh Water |

Material Specifications for Micro-Resistance Slow-Closing Butterfly Check Valve

|

Valve Body |

Cast Iron, Cast Steel, Stainless Steel |

|

Valve Disc |

Carbon Steel |

|

Valve Stem, Cylinder, Piston |

Stainless Steel |

|

Spring |

Stainless Steel |

|

Valve Seat |

Nitrile Rubber |

Dimensions for Micro-Resistance Slow-Closing Butterfly Check Valve

|

Nominal Pressure |

Nominal Diameter DN (mm) |

Dimensions (mm) |

Nominal Pressure |

Nominal Diameter DN (mm) |

Dimensions (mm) |

||||

|

L |

H |

H1 |

L |

H |

H1 |

||||

|

1.0/1.6/2.5 MPa |

40 |

140 |

200 |

88 |

1.0/1.6/2.5 MPa |

350 |

290 |

480 |

297 |

|

50 |

150 |

215 |

98 |

400 |

310 |

550 |

324 |

||

|

65 |

170 |

225 |

108 |

450 |

330 |

585 |

351 |

||

|

80 |

180 |

235 |

118 |

500 |

350 |

640 |

379 |

||

|

100 |

190 |

280 |

130 |

600 |

390 |

720 |

434 |

||

|

125 |

200 |

290 |

148 |

700 |

430 |

780 |

491 |

||

|

150 |

210 |

310 |

172 |

800 |

470 |

840 |

549 |

||

|

200 |

230 |

350 |

210 |

900 |

510 |

990 |

600 |

||

|

250 |

250 |

415 |

240 |

1000 |

550 |

1050 |

655 |

||

|

300 |

270 |

450 |

264 |

1200 |

630 |

1210 |

770 |

||

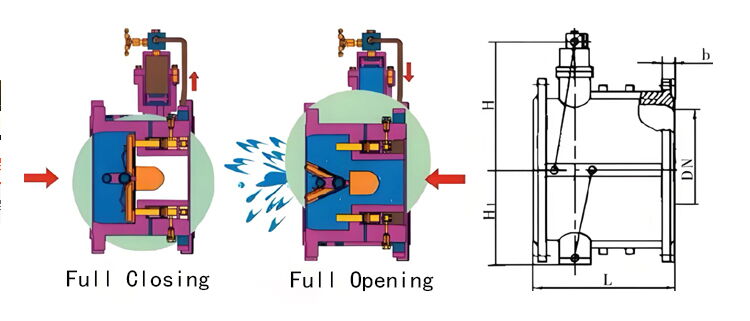

Principle of Operation for Micro-Resistance Slow-Closing Butterfly Check Valve

The opening and closing of the check valve rely on the flow and force of the medium to automatically open or close, preventing the backflow of the medium. Check valves generally come in four types: lift, swing, butterfly, and horizontal. The vertical lift check valve should be installed horizontally, while the vertical swing check valve and bottom valve are usually installed vertically. The swing check valve's installation position is not limited and can be installed horizontally, but it can also be installed vertically or on an inclined pipeline.

Note: The check valve only allows the medium to flow in one direction and special attention should be paid to the direction of flow. The direction of the medium's normal flow should be consistent with the direction indicated by the arrow on the valve body; otherwise, it will interrupt the normal flow of the medium.

The principle of the micro-resistance slow-closing butterfly check valve is to rely on the force of the medium entering the valve to push the two valve flaps to open. At the same time, the pressure of the medium enters the lower part of the piston chamber through the oilway, pushing the piston upward. The oil in the upper part of the piston is expelled through the needle valve into the two small air chambers at the ends of the valve body, causing the piston in the small air chamber to extend. When the pressure of the medium entering the valve drops below the outlet pressure, the medium will flow back. At this time, under the action of the spring and the force of the medium flowing back, the valve flaps will automatically close. However, due to the piston rod being in an extended position, the valve flaps cannot fully close, leaving about 20% of the area for the medium to pass through, thus eliminating the effect of water hammer. The valve flaps are divided into two parts by the piston to first quickly close and then slowly close in two steps, which not only prevents motor reversal but also serves to eliminate noise.

Performance Characteristics of Micro-Resistance Slow-Closing Butterfly Check Valve

1. Small size, light weight, and structural length is only about one-third of the swing check valve.

2. Excellent slow-closing system performance, not affected by the impact of the medium in the pipeline. The valve flaps close first and then slowly, which can prevent destructive water hammer.

3. Rubber soft sealing, good sealing performance, wear-resistant, and long service life.

4. Rubber cushioning, stable opening and closing, no vibration, no noise.

5. Compared to the old check valve, it has a smaller flow resistance and significant energy-saving effects.