(API 624 Additional High Temperature Version)

Key Specifications / Features

The Trunnion Mounted Ball Valve is engineered for high-performance applications, meeting API 6D, ASME B16.34, and ASTM A351 CF8 standards. With a 6-inch (DN150) size and Class 600 LB rating, it features low emission design and metal seating for durability in demanding conditions. The valve's PN100 pressure rating and flanged ends ensure secure, reliable installation, making it ideal for industries requiring precise flow control and high-pressure resistance.

- Model No.: MV-20250408-LTMSBV-04

- Hits: 15

- Categories: Low Torque Metal Seated Ball Valve

- Tags: Trunnion Mounted Ball Valve, ASTM A351 CF8 Ball Valve, API 6D Ball Valve

Detail Information

Product Name: Trunnion Mounted Ball Valve

Design Standard: API 6D, ASME B16.34

Body Material: ASTM A351 CF8

Size: 6 Inch, DN150

Pressure: Class 600 LB, PN100

End: Flanged

Product Range

Structure: Trunnion Mounted Ball

Size Range: NPS 1/2-36 Inch, DN15-DN900

Pressure Range: Class 150-2500 LB, PN20-PN420

Bonnet Type: Side Entry (2-piece or 3-piece split body)

Bore: Full/Reduced Bore

Body Material: ASTM A216 WCB, A352 LCB, A351 CF8, CF3, CF8M, CF3M, etc.

Seat Material:

(Soft Seat) PTFE, RPTFE, Nylon, PEEK, PCTFE

(Metal Seat) STL, HVOF Coating

Features: Fire Safe, Anti-static, Anti-blowout, Double Block & Bleed Design

Standards

Design: API 6D, ASME B16.34

Inspection & Testing: API 598

Marking: MSS SP-25

Pressure/Temperature Rating: ASME B16.34

Fugitive Emission: ISO 15848

Face-to-Face: ASME B16.10

End-to-End: Manufacturer Standard or ASME B16.10

Socket Welding Ends: ASME B16.11

Screwed Ends: ASME B1.20.1

Flange Ends: ASME B16.5

Butt Welding Ends: ASME B16.25

For 6D ball valve design, we focus more on the details, such as deep control over the performance of non-metallic materials. We are well aware that many so-called explosion-proof O-rings used in ball valves in China are not truly explosion-proof. Most valve manufacturers only use "hardness compliance" as the material acceptance criterion, which is not enough to determine whether an O-ring is genuinely explosion-proof.

Many O-ring suppliers understand this. As long as the hardness meets the required range, they supply the product. In reality, truly explosion-proof O-rings require low-temperature, long-duration vulcanization. However, this slows down their production. To improve efficiency, they increase the vulcanization temperature and shorten the time, compromising quality.

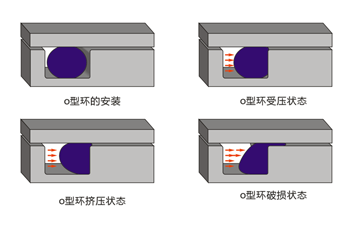

In high-pressure applications, if the O-ring is only hard but lacks toughness, excessive rigidity leads to stress concentration on the sealing surface and may cause cracking. If it is tough but not hard enough, extrusion deformation and sealing failure can occur. What you mentioned as "both hard and tough" is actually about balancing Shore hardness (to provide rigid support) with elongation at break and rebound resilience (to resist deformation). This is crucial for preventing media penetration and cracking under extreme conditions. When media such as gas or flammable liquids enter micro-cracks in the rubber, high pressure can create a "splitting effect", resulting in seal failure or even serious safety incidents.

Our deep involvement, knowing applications better than the suppliers and understanding materials better than the users, has allowed us to establish our own technical voi ce and authority.

ce and authority.

Therefore, in many high-pressure valves, O-ring seal failure at the valve seat is common. Many engineers choose to add backup rings to prevent extrusion and tearing. However, the real issue often lies in the O-ring itself. When it has toughness but lacks hardness, it indicates that the material is not a qualified explosion-proof compound.

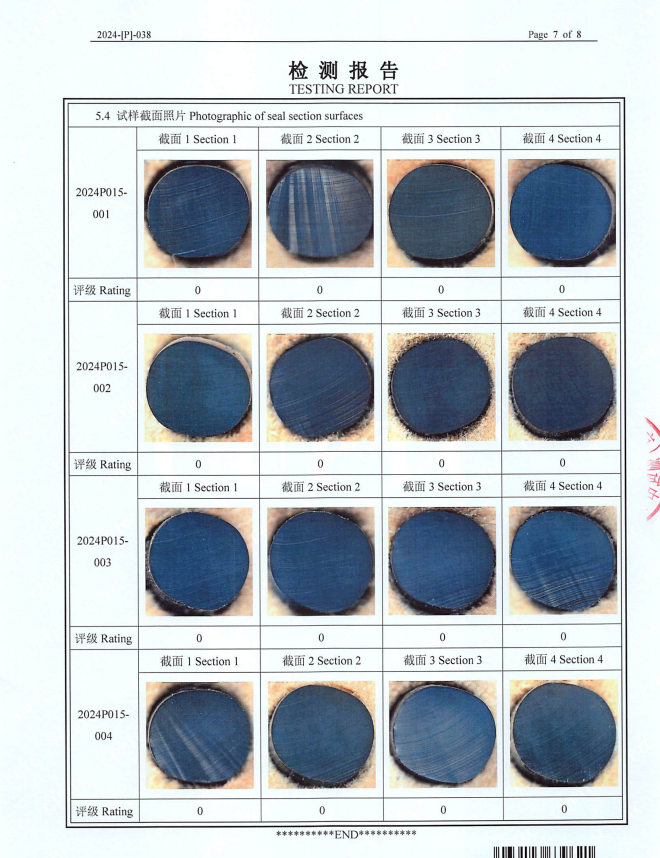

We've tested such O-rings at China University of Petroleum (Beijing) for explosion-proof performance. Although they met hardness requirements, their explosion resistance failed completely. Under high-pressure methane gas impact, the O-rings developed full-surface cracking. This poses significant safety risks for pipeline ball valves.

Qualified explosion-proof tests under high-pressure methane gas impact show only clean slicing with absolutely no cracks.

Similar Products

Top Entry Trunnion Ball Valve, API 6D, ASTM A351 CF8, 32 IN

ASTM A351 CF8M Trunnion Ball Valve, API 6D, 2PC, 8 IN, CL600

API 6D Trunnion Ball Valve, A216 WCB, 8 IN, CL600, Top Entry