(API 624 Additional High Temperature Version)

Key Specifications / Features

The Wafer Ball Valve Factory in China specializes in producing high-quality ball valves that meet a variety of industrial needs. These valves are constructed from ASTM A216 WCB and stainless steel materials such as SS 304 and SS 316, ensuring durability and corrosion resistance. They are available in sizes ranging from DN15 to DN200 (1/2 to 8 inches) and can handle pressures from PN16 to PN64, as well as Class 150 to 400 LB. These valves are designed with flanged or wafer ends for easy installation and maintenance.

- Model No.: MV-20250702-LTMSBV-01

- Hits: 17

- Categories: Low Torque Metal Seated Ball Valve

- Tags: Wafer Ball Valve, ASTM A216 WCB Ball Valve, SS 304 Ball Valve

Detail Information

Product Name: Wafer Ball Valve

Body Materials: ASTM A216 WCB, SS 304, SS 316

Size Range: DN15-DN200, 1/2-8 Inch

Pressure Range: PN16-PN64, Class 150-400 LB

End Connection: Flanged, Wafer

Temperature Range: -20°C to 60°C

Medium: Water, Oil, Gas, ect

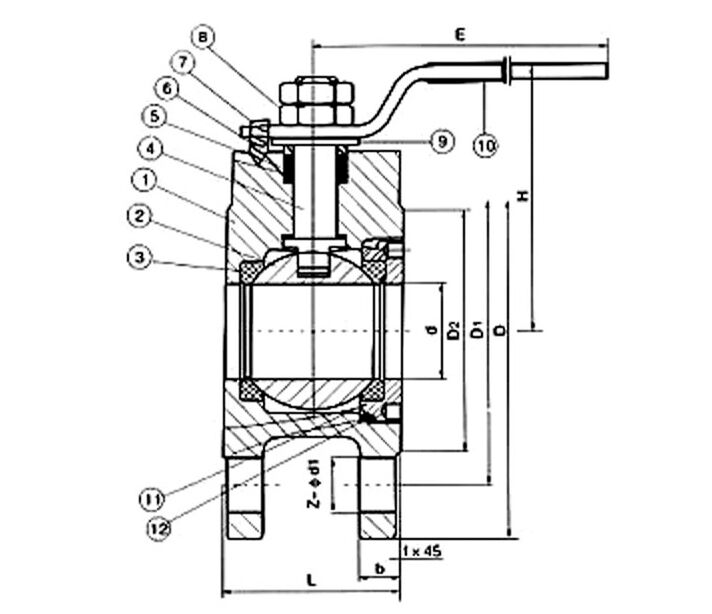

Wafer Type Thin Ball Valve

The wafer type thin ball valve is connected between two pipe flanges using double-headed bolts. It has a simple structure, small size, and light weight, composed of only a few parts. It can be quickly opened and closed by rotating 90°, with simple operation and good flow control characteristics. When the ball valve is in the open position, the valve core has no resistance, thus the pressure drop through the valve is very low, providing good flow control characteristics.

Applications: Widely used in petroleum, chemical, metallurgy, power stations, light industry, and other fields, for automatic control or cut-off control of oil, water, gas, paper pulp, or fibrous fluids.

Wafer Ball Valve Features

Anti-blow-out stem design

Anti-static design

Pressure balance hole

Automatic packing adjustment design

High platform in accordance with ISO 5211 design

Optional fireproof design

The valve body has an integrated structure, with precise machining and assembly. The ball core is installed from one end, tightened with a ring, ensuring good contact and sealing between the soft sealing seat and the ball core. At the same time, the ring gasket also achieves good sealing, making the valve leak-free during operation.

Due to the integrated structure of the valve body, this valve achieves a short flange distance and significantly reduces the overall weight, only about 50% of that of similar general ball valves.

|

Diameter |

1/2 Inch |

3/4 Inch |

1 Inch |

1-1/4 Inch |

1-1/2 Inch |

2 Inch |

2-1/2 Inch |

3 Inch |

4 Inch |

5 Inch |

6 Inch |

8 Inch |

|

d |

15 |

19 |

23.5 |

30 |

36 |

45 |

58 |

67 |

76 |

100 |

125 |

195 |

|

L |

32 |

38.5 |

45 |

55 |

62 |

72 |

95 |

120 |

145 |

200 |

225 |

275 |

|

D |

95 |

105 |

115 |

135 |

145 |

160 |

180 |

195 |

215 |

245 |

280 |

335 |

|

D1 |

65 |

75 |

85 |

100 |

110 |

125 |

145 |

160 |

180 |

210 |

240 |

295 |

|

D2 |

45 |

55 |

65 |

78 |

85 |

100 |

120 |

135 |

155 |

185 |

210 |

265 |

|

H |

62 |

70 |

79 |

86 |

92 |

102 |

158 |

172 |

187 |

200 |

240 |

278 |

|

E |

110 |

125 |

135 |

150 |

150 |

180 |

250 |

300 |

350 |

650 |

840 |

1000 |

|

b |

14 |

14 |

16 |

16 |

18 |

20 |

22 |

24 |

24 |

26 |

26 |

28 |

|

z-d1 |

4-14 |

4-14 |

4-14 |

4-18 |

4-18 |

4-18 |

4-18 |

8-18 |

8-18 |

8-18 |

8-23 |

12-20 |

|

f |

2 |

2 |

2 |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

Similar Products

3 Piece Ball Valve, ASME B16.34, SS 304, 1 Inch, 1000 WOG

Ceramic Ball Valve, ASME B16.34, Pneumatic, SS 304, DN100

Electric Tri-Clamp Ball Valve, SS 304/SS 316L, 3PC, 1/4-4 IN