(API 624 Additional High Temperature Version)

Key Specifications / Features

The Remote Float Level Control Valve Plant offers a versatile range of high-quality valves designed for precise liquid level control in various industrial applications. These valves are available in multiple materials including cast iron, cast steel, stainless steel, and brass, ensuring compatibility with different media and environments. They come in a wide range of sizes from DN20 to DN800 (3/4 to 32 inches) and pressure ratings from PN10 to PN25, making them suitable for diverse operational requirements. The valves feature flanged ends and comply with international standards such as DIN, API, and ANSI, guaranteeing reliability and interoperability.

- Model No.: MV-20250705-LECV-01

- Hits: 10

- Categories: Low Emission Control Valves

- Tags: Float Level Control Valve, Remote Control Valve, Stainless Steel Control Valve

Detail Information

Product Name: Remote Float Level Control Valve

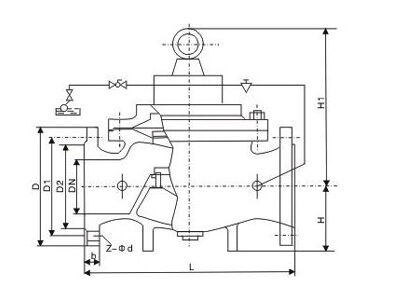

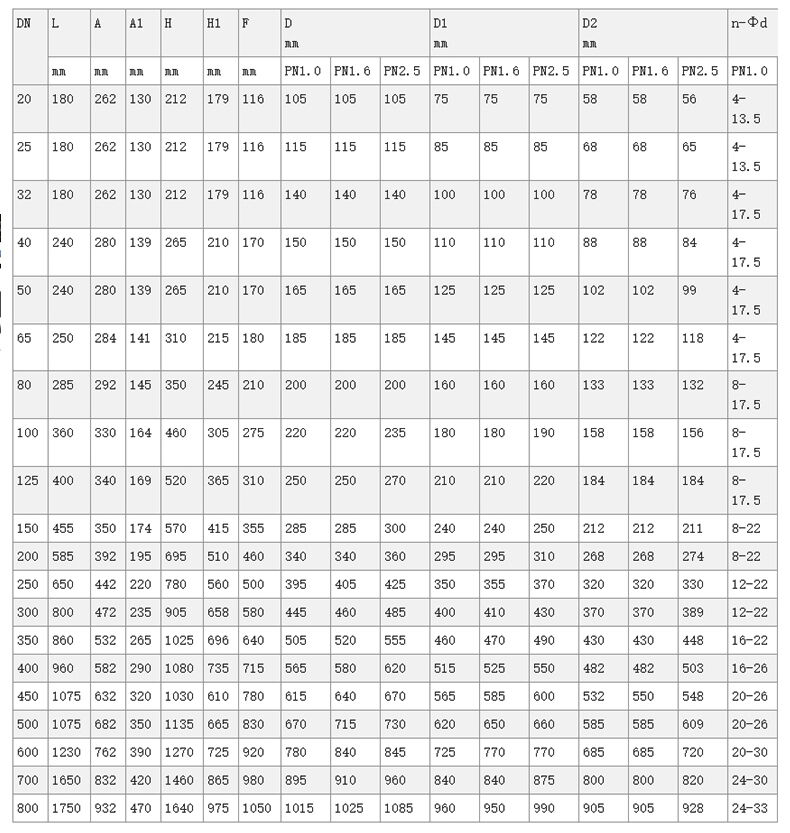

Nominal Diameter: DN20-DN800, 3/4-32 Inch

Working Pressure: 1.0MPa to 2.5MPa, PN10-PN25, Class 150-300 LB

Applicable Temperature: -20°C to +80°C

Body Material: Cast Iron, Cast Steel, Stainless Steel, Brass

Connection Method: Flanged

Functional Role: Water Level Control

Manufacturing Standards: National Standard GB, German DIN, American API, ANSI.

Applicable Medium: Water, sewage, water supply and drainage

Remote Float Level Control Valve Product Introduction

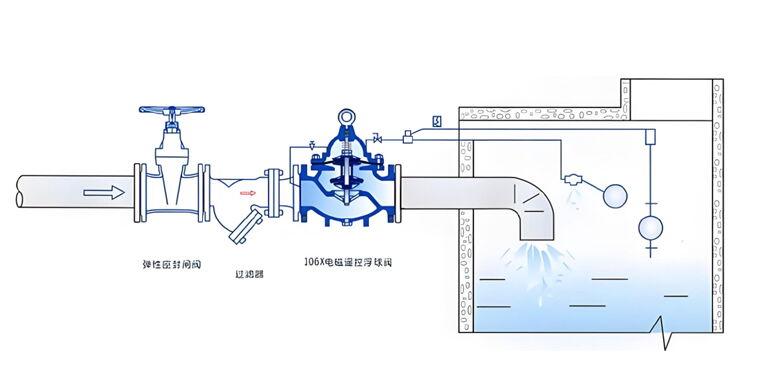

The diaphragm-type remote float level control valve is a hydraulically operated valve with multiple functions. The remote float level control valve is primarily installed at the water inlet of water tanks or elevated water towers. When the water level reaches the preset height, the main valve is controlled by the float pilot valve to close the water inlet and cease water supply; when the water level decreases, the main valve is controlled by the float pilot valve to open the water inlet and replenish the water tank, achieving automatic water replenishment. The liquid level control is precise and unaffected by water pressure; the remote float level control valve can be installed at any position according to the height of the water tank and the available space. It offers convenient maintenance, adjustment, and inspection, with reliable sealing and a long service life. The diaphragm valve is reliable in performance, high in strength, and flexible in operation. It is suitable for pipes with a diameter of DN450mm or less. For pipes with a diameter of DN500mm or more, it is recommended to use the piston type.

Technical Specifications

|

Nominal Pressure (Mpa) |

Shell Test Pressure (MPa) |

Seal Test Pressure (MPa) |

Applicable Medium |

Medium Temperature (°C) |

|

1.0 |

1.5 |

1.1 |

Water |

0-80 |

|

1.6 |

2.4 |

1.76 |

||

|

2.5 |

3.75 |

2.75 |

Main Components and Materials

|

Component Name |

Material |

|

Valve Body and Cover |

WCB |

|

Valve Seat and Disc |

Copper Alloy |

|

Sealing Ring O-ring |

Nitrile Rubber |

|

Valve Stem |

2Cr13 |

|

Spring |

50CrVA |

|

Needle Valve |

Copper Alloy |

|

Ball Valve |

Copper Alloy |

|

Float Valve |

Copper Alloy |

|

Miniature Filter |

Stainless Steel |

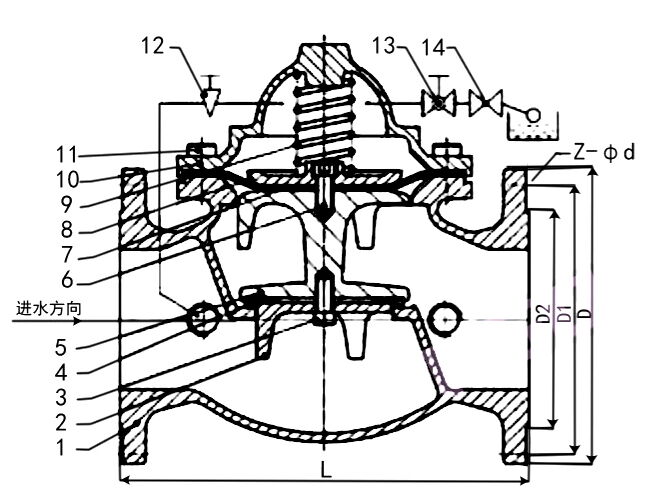

1. Valve Body

2. Guide Plate

3. Bolt

4. O-ring

5. Main Valve Disc

6. Bolt

7. Diaphragm

8. Diaphragm Plate

9. Spring

10. Valve Cover

11. Bolt

12. Needle Valve

13. Ball Valve

14. Float Valve

Similar Products

Top Guided Control Valve, 1/2-8 Inch, CL150-600, Unbalanced

Cage Guided Control Valve, CS, SS, AS, 1.5-24 IN, Single Seat

Pneumatic 3-Way Control Valve, Diverting/Converging, 1-20 IN